A variable capacitor is an electrical component used to temporarily store electrical energy in an electric field. Unlike fixed capacitors, the capacitance of a variable capacitor can be altered by varying certain parameters such as the overlapping area of plates, the distance between them, or the dielectric material. They are widely used in applications like tuning circuits, oscillators, and filters.

Construction of Variable Capacitor

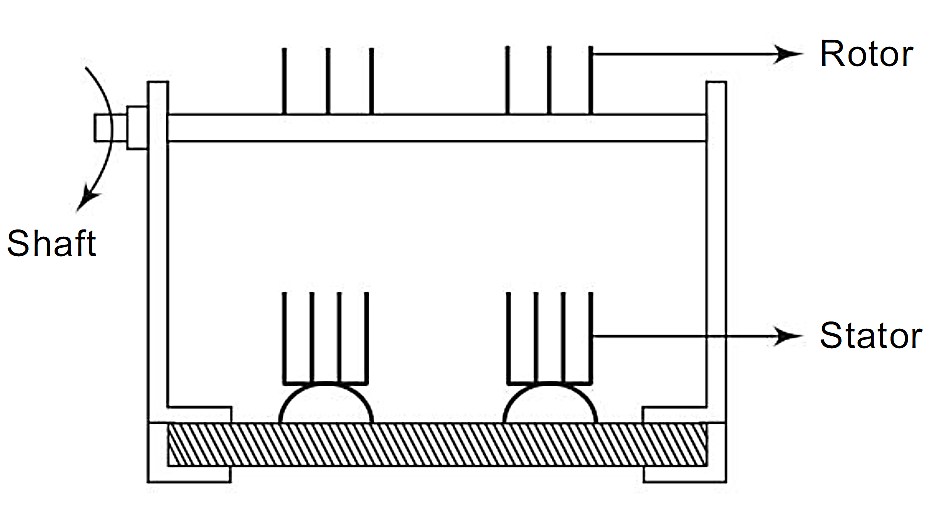

Figure 1.

The construction (see figure 1) of a variable capacitor consists of the following major parts:

- Rotor: A set of movable conductive plates. These plates rotate to adjust the capacitance by changing the overlapping area with the fixed plates.

- Stator: A set of fixed conductive plates. These plates remain stationary and interact with the rotor plates to form the capacitor.

- Shaft: A mechanical control element connected to the rotor. By rotating the shaft, the rotor’s position relative to the stator changes, altering the capacitance.

- Dielectric Material: Air is commonly used as the dielectric in variable capacitors, though other materials may also be used depending on the application.

- Housing: Encloses the assembly to provide mechanical support and protection from external elements.

Working Principle of Variable Capacitor

The variable capacitor operates on the same fundamental principle as a fixed capacitor, where capacitance is given by:

\begin{equation}

C = \frac{\varepsilon A}{d}

\end{equation}

Where:

C = Capacitance (Farads)

ε = Permittivity of the dielectric material (Farads per meter)

A = Overlapping area of the plates (square meters)

d = Distance between the plates (meters)

In a variable capacitor, adjusting the rotor changes the overlapping area A, thereby altering the capacitance. In certain designs, the distance d can also be varied mechanically. This principle allows the capacitance to be fine-tuned for specific applications.

Types of Variable Capacitors

| Type | Description |

|---|---|

| Air-Gap Capacitors | Use air as the dielectric, commonly found in tuning circuits for radios. |

| Vacuum Variable Capacitors | Use a vacuum as the dielectric, suitable for high voltages and frequencies. |

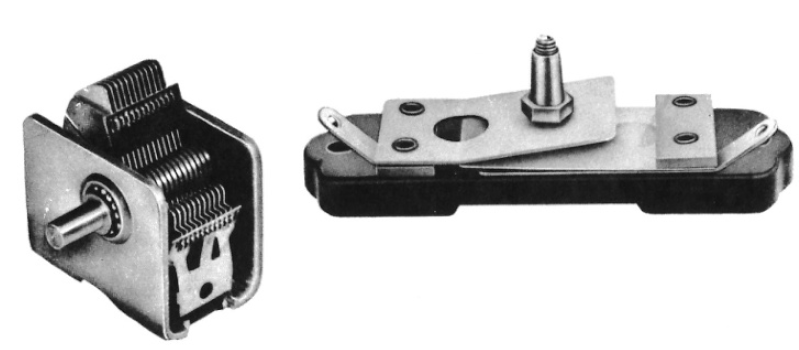

| Trimmer Capacitors | Small, manually adjustable capacitors for fine-tuning circuits. |

| Dielectric Variable Capacitors | Use dielectric materials other than air for better stability and higher capacitance. |

| Electronic Variable Capacitors | Utilize semiconductor materials to vary capacitance electronically without mechanical movement. |

Advantages of Variable Capacitors

- Adjustable Capacitance: Provides flexibility for tuning and calibration.

- Versatile Applications: Suitable for use in various circuits, from RF to audio frequencies.

- Compact Design: Trimmer capacitors are especially compact and fit into small circuits.

- Cost-Effective: Widely available and relatively inexpensive for most designs.

Disadvantages of Variable Capacitors

- Mechanical Wear: Moving parts may degrade over time.

- Limited Stability: Prone to drift due to temperature or mechanical vibrations.

- Lower Capacitance Range: Typically offer smaller capacitance values compared to fixed capacitors.

- Manual Adjustment: In most cases, manual tuning is required, which can be less convenient.

Applications of Variable Capacitors

Variable capacitors are essential in numerous applications, including:

- Tuning Circuits: Used in radios, televisions, and communication systems for frequency tuning.

- Oscillators: Employed in LC oscillators to adjust resonant frequencies.

- Filters: Help in creating tunable filters for signal processing.

- Matching Networks: Optimize the impedance matching in RF circuits.

- Measuring Instruments: Used in capacitance bridges and other test equipment.