The Star Delta Starter used to starting the standard squirrel cage induction motors with both ends of each of the three windings brought out (six terminals) are known as star-delta motors.

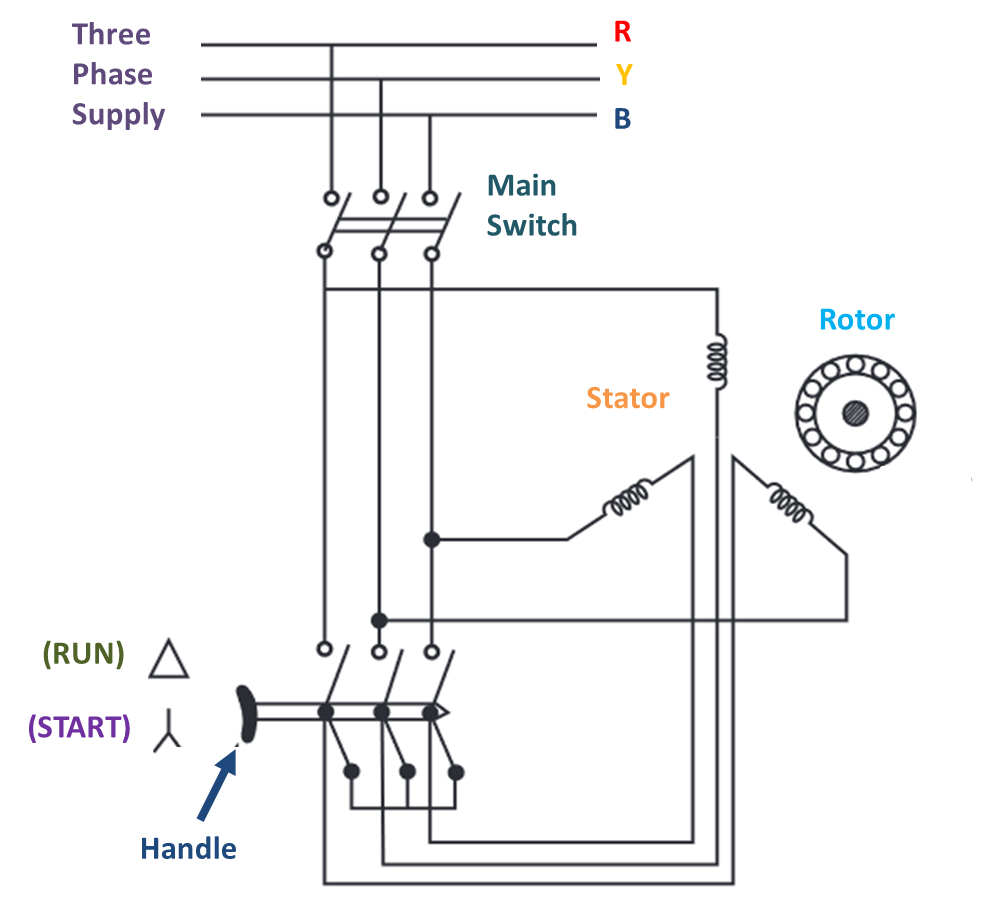

The Star Delta Starter connects the three stator windings in star across the rated supply voltage at the time of starting. After the motor attains speed the same windings are connected in delta across the same supply voltage through a change over switch. This is shown in Fig. 1.

Fig.1. Star Delta Starter.

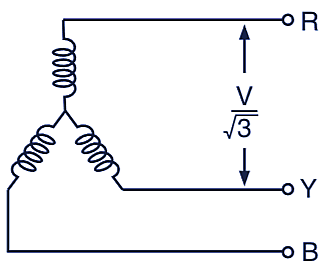

Fig. 2: Winding in star for starting

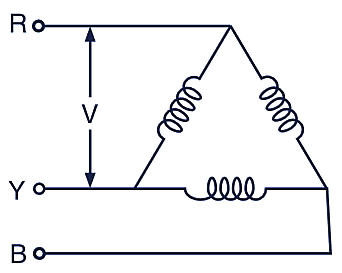

Fig. 3: Winding in delta for running

On the Star Delta Starter, STAR (start) and DELTA (run) are marked. A mechanical interlocking device is also provided to it so that mechanical handle can go to DELTA position only after going through STAR position, Fig. 1 shows the star-delta starter. When handle is moved on to star position the winding get connected in star (Fig. 2). The voltage per phase become 1/√3 times the previous voltage i.e. 50% of the nominal voltage (Fig. 3). The phase current is also reduced by 1/√3 times.

As the motor pick up speed the handle is moved to “run position”, thereby full line voltage is supplied to the winding and the motor will then mn on normal speed taking normal current.

Construction of Star Delta Starter

Star-delta starter consists of contacts operated through handle, no volt relay coil, overload relay and contact. To stop the motor stop button is provided. A mechanical interlocking device is also provided to it so that handle can go to ‘DELTA’ position only after going through ‘STAR’ position.

Working of Star Delta Starter

For starting, the handle is pushed to ‘start’ position. When the motor gains speed the handle is quickly moved to ‘Run’ position (Fig. 1). The no-volt release coil is connected between the two lines and becomes magnetised and thereby holds the handle in running position. For stopping the ‘stop’ button is pressed. This will disconnect the circuit of no-volt coil. The no-volt coil gets demagnetised and releases the handle.

If due to any reason the load current is increased the overload relay contact will disconnect the electric circuit of no-volt coil through a switch. The no-volt coil will become demagnetised and release the handle.

Overload Relay

It consists of three thermal bimetallic strips. which will bend due to heating of large current. This will disconnect the circuit of no-volt coil and leave the handle of ‘OFF’ position.

No-Volt Relay Coil

The starter is also provided with no-volt coil which is connected between the two lines in series with stop button and overload contact. When the motor is running the coil becomes magnetised and holds the handle in ‘Run’ position. When the supply fails no-volt coil will be demagnetised and leave the handle in ‘OFF’ position.

Advantages of Star Delta Starter

- It is cheap.

- It is robust in construction.

- Under low load condition, it enables the motor to be connected in star thereby improving the efficiency as well as power factor of the motor.

Disadvantages of Star Delta Starter

- It provides a fixed (i.e. 1/3rd) starting torque. consequently, it can not be used for motors requiring torque high or lower than this value for starting.

- It can only be used for motors designed for delta-run.

- All the six terminals of the three stator windings are required to be brought out for connections at the time of starting

Types of Star Delta Starter

Star-delta starter can be of two types.

- Manually operated star-delta starter

- Automatic operated star-delta starter.