A relay is an electrically operated switch that uses an electromagnet to mechanically operate a set of contacts. It is widely used in circuits to control a high-power or high-voltage circuit with a low-power signal, providing isolation between the control and load circuits.

What is a Relay?

A relay is an electromechanical device that uses an electromagnetic coil to operate a switch. It allows low-power circuits to control high-power devices by opening or closing circuits using an energized or de-energized coil. Relays are fundamental in automation, control systems, and electrical circuits.

Construction of a Relay

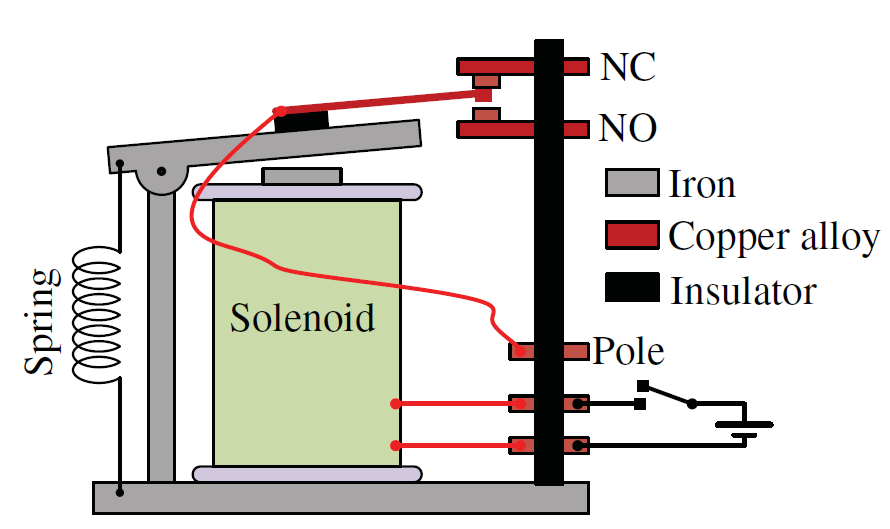

Figure 1: The Relay.

A relay is an electrically operated switch that allows one circuit to control another, often with different voltage or current levels. It is used to isolate and protect low-power circuits or to control high-power loads. Its construction as shown in Figure 1,

- Solenoid (Coil): A wire wound around a magnetic core that creates a magnetic field when current flows through it.

- Spring: Maintains the armature’s position when no current flows through the coil.

- Iron Core: Increases the magnetic effect of the solenoid.

- Contacts:

- NC (Normally Closed): Connected to the pole when the relay is not energized.

- NO (Normally Open): Disconnected from the pole when the relay is not energized.

- Pole: The movable arm that toggles between NC and NO contacts.

- Insulators: Prevent electrical conduction between different parts.

- Copper Alloy Contacts: Ensure efficient conduction when connected.

Working of a Relay

- Energized State: When current flows through the coil, the solenoid generates a magnetic field. The magnetic force pulls the armature, moving the pole from NC to NO.

- De-energized State: When current is removed, the spring pushes the armature back to its original position, reconnecting NC.

Working Principle of a Relay

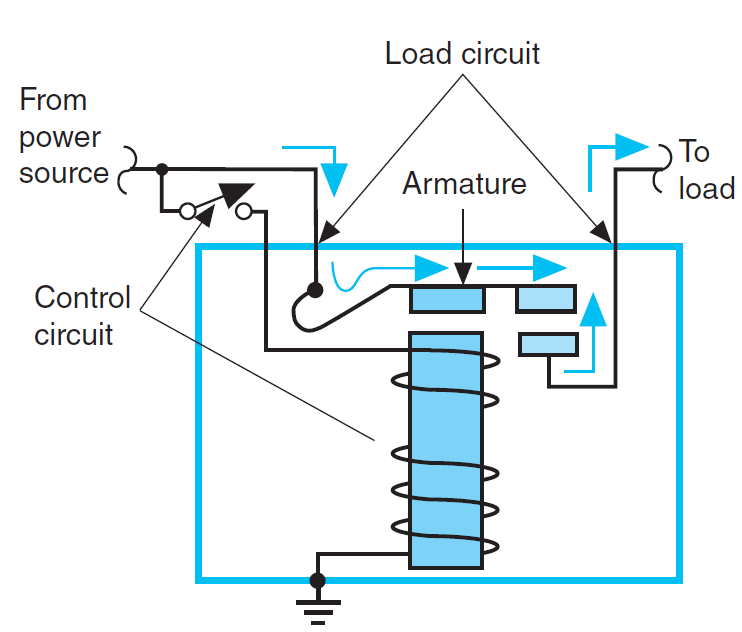

A relay operates on the principle of electromagnetism to control the flow of electricity in a circuit. Here’s how it works step-by-step:

- Energizing the Coil: When a low voltage is applied across the relay’s control circuit (coil), an electric current flows through the coil, generating a magnetic field.

- Movement of the Armature: The magnetic field attracts a movable metal component called the armature, causing it to move.

- Switching the Contacts: The movement of the armature changes the position of the relay’s contacts:

- Normally Open (NO): Contacts close to complete the circuit.

- Normally Closed (NC): Contacts open to break the circuit.

- Load Circuit Control: The switching action allows a high-power or high-voltage load circuit to be controlled using the low-power signal from the control circuit.

- De-energizing the Coil: When the control voltage is removed, the magnetic field collapses, and a spring mechanism returns the armature to its original position, resetting the contacts.

Types of Relays

Relays can be categorized based on different criteria, including construction, operating principles, and application. Below are common types:

| Type | Description |

|---|---|

| Electromechanical Relays (EMR) | Utilize physical movement of components for switching. Examples include general-purpose and reed relays. |

| Solid-State Relays (SSR) | Use semiconductor devices for switching, offering faster and more durable operation. |

| Time-Delay Relays | Introduce a delay in switching operations, commonly used in industrial control systems. |

| Thermal Relays | Operate based on temperature changes to protect devices from overheating. |

| Polarity-Sensitive Relays | Respond to specific polarities of current, suitable for DC circuits. |

| Protective Relays | Monitor electrical parameters like voltage and current to ensure safety. |

| Latching Relays | Maintain their position even after the coil is de-energized, useful in memory storage applications. |

Advantages of Relays

- Isolation: Electrically isolates the control and load circuits.

- Low Power Consumption: Operates with minimal control signal power.

- High Reliability: Durable and can handle frequent switching.

- Versatility: Suitable for a wide range of applications.

- Cost-Effective: Affordable compared to other switching devices.

- Customizability: Available in various configurations for specific requirements.

Disadvantages of Relays

- Wear and Tear: Mechanical components are prone to failure over time.

- Slower Operation: Electromechanical relays have slower switching speeds compared to solid-state devices.

- Contact Arcing: Can occur in high-power circuits, reducing lifespan.

- Size: Bulkier compared to modern semiconductor-based alternatives.

Applications of Relays

Relays find extensive use in various fields and applications:

- Automotive: Controlling headlights, horns, and fuel pumps.

- Industrial Automation: Used in programmable logic controllers (PLCs) and motor control systems.

- Home Appliances: Found in washing machines, air conditioners, and microwave ovens.

- Telecommunication: Switching circuits in telecommunication networks.

- Power Systems: Protective relays safeguard equipment from overcurrent and voltage surges.

- Medical Equipment: Used in diagnostic machines and life-support systems.

- Aerospace: Relays control circuits in aircraft and space systems.

- Lighting Control: Used in automated lighting systems for efficient power management.

Conclusion

Relays are indispensable components in electrical and electronic systems. Their ability to control high-power circuits with low-power signals makes them a key element in automation and safety systems. While newer technologies like solid-state relays are gaining popularity, traditional electromechanical relays continue to serve as reliable, cost-effective solutions for various applications.