Casing capping wiring is one of the traditional electrical wiring methods used in residential, commercial, and industrial buildings. This method involves running electrical wires inside a casing (usually made of PVC or wood) and covering them with a capping for protection. It is known for its safety, durability, and ease of installation.

What is Casing Capping Wiring?

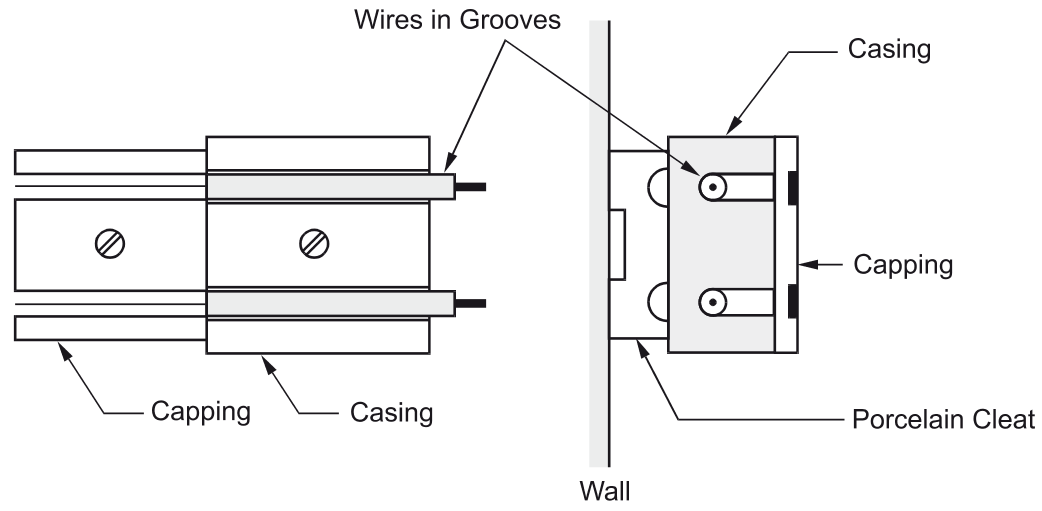

Casing capping wiring is a surface wiring system where insulated conductors are placed inside rectangular, enclosed channels called casings. These casings are covered with caps to protect the wires from mechanical damage, dust, and moisture. It provides a neat and organized wiring layout.

Parts of Casing Capping Wiring

- Casing: A rectangular conduit made of PVC or wood that holds the electrical wires securely.

- Capping: A cover placed over the casing to protect and conceal the wires.

- Wires: PVC-insulated conductors used for power distribution.

- Porcelain Cleats: Supports the casing in certain installations.

- Screws and Bolts: Used to fix the casing and capping onto the wall or ceiling.

- Wall or Ceiling: The supporting structure where the wiring is installed.

Working Principle of Casing Capping Wiring

- The casing is fixed onto the wall or ceiling using screws or nails at regular intervals.

- Electrical wires are laid inside the grooves of the casing.

- The capping is then placed on top of the casing, securing the wires inside.

- The wires remain protected from external factors such as moisture, dust, and mechanical damage.

- Electrical connections are made at junction boxes and switches as per the wiring layout.

Advantages of Casing Capping Wiring

- Neat and Organized Appearance: Conceals wires and provides a clean look.

- Cost-Effective: Cheaper compared to conduit wiring systems.

- Easy Installation: Simple to install and does not require specialized tools.

- Good Protection: Protects wires from mechanical damage and environmental factors.

- Easy Maintenance and Modification: Wires can be easily accessed, replaced, or extended.

- Fire Resistance: When made from PVC, it provides insulation against fire hazards.

Disadvantages of Casing Capping Wiring

- Bulky Installation: Takes up more space compared to concealed wiring.

- Limited Lifespan: Wooden casing may degrade over time due to moisture and pests.

- Not Suitable for High Voltage: Best for low to medium voltage applications.

- Vulnerability to Rodents: Rodents may chew through casing if not properly maintained.

- Less Aesthetic for Modern Buildings: Exposed casing may not blend well with contemporary interior designs.

Applications of Casing Capping Wiring

- Residential Buildings: Used in houses and apartments for lighting and power circuits.

- Commercial Establishments: Installed in shops, offices, and retail outlets.

- Industrial Units: Used for light-duty electrical installations in workshops and factories.

- Educational Institutions: Common in schools and colleges for electrical distribution.

- Temporary Installations: Ideal for sites where frequent wiring modifications are needed.

Conclusion

Casing capping wiring is a traditional yet effective wiring method offering safety, ease of maintenance, and an organized layout. While it has some disadvantages, such as bulkiness and limited suitability for high-voltage applications, it remains a cost-effective and reliable solution for many electrical installations. Its ability to protect wires from external damage makes it a preferred choice in various residential, commercial, and industrial settings.