A rheostat is an important electrical component widely used in power and control circuits. It is mainly used to control current in a circuit without interrupting the supply. Rheostats are commonly found in laboratories, industrial equipment, motor control systems, and high-power applications.

What is a Rheostat?

Definition: A rheostat is a type of variable resistor designed to vary the resistance in a circuit to control the current flow, usually in high-power applications.

Unlike small potentiometers used in electronic circuits, a rheostat is built to handle large currents and high power dissipation. By changing the effective length of the resistive element, the resistance value changes, which in turn controls the current according to Ohm’s Law.

Rheostat Diagram

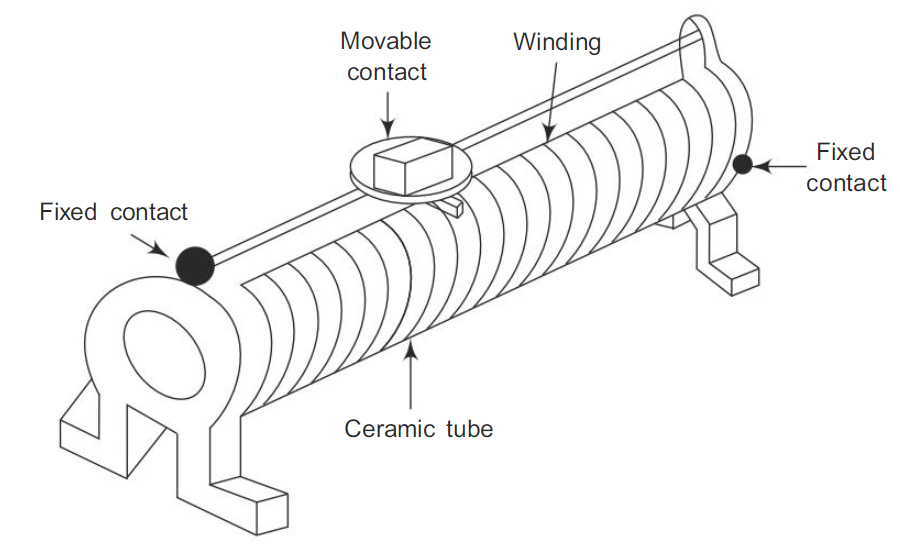

The diagram below shows the basic construction of a wire-wound rheostat, including fixed contacts, movable contact, resistive winding, and ceramic tube.

Construction of Rheostat

The construction of a rheostat is simple yet robust, allowing it to operate reliably under high temperature and heavy current conditions.

Main Parts of a Rheostat

- Resistive Element: Usually made of nichrome or manganin wire wound uniformly.

- Ceramic Tube or Core: Acts as an insulating and heat-resistant base.

- Fixed Contacts: Connected to the ends of the resistive wire.

- Movable Contact (Slider): Slides over the resistive wire to vary resistance.

- Enamel Coating: Protects the wire and improves insulation.

The resistive wire is wound on a ceramic tube and coated with vitreous enamel, except at the track where the movable contact touches the wire. This design allows the rheostat to withstand temperatures up to 300°C.

Working Principle of Rheostat

The working of a rheostat is based on Ohm’s Law:

V = I × R

When the movable contact (slider) is moved along the resistive winding, the effective length of the resistance wire included in the circuit changes.

- If the slider moves to increase the wire length → Resistance increases → Current decreases.

- If the slider moves to decrease the wire length → Resistance decreases → Current increases.

Thus, without switching off the supply, the current in the circuit can be smoothly controlled. This makes rheostats extremely useful in applications where gradual control is required.

Types of Rheostat

Rheostats can be classified based on construction, cooling method, and application.

The major types are listed below.

| Type of Rheostat | Construction / Feature | Typical Applications |

|---|---|---|

| Wire-Wound Rheostat | Resistive wire wound on ceramic core | Laboratories, motor control |

| Slide Rheostat | Slider moves linearly over resistance | Educational experiments |

| Rotary Rheostat | Rotating arm varies resistance | Industrial control panels |

| Liquid Rheostat | Uses electrolyte as resistance medium | Starting large motors |

| Air-Cooled Rheostat | Cooled naturally by air | Medium power applications |

| Oil-Cooled Rheostat | Immersed in oil for heat dissipation | Heavy duty industrial loads |

Advantages of Rheostat

- Simple and rugged construction

- Capable of handling high current and power

- Smooth and precise current control

- High temperature tolerance

- Reliable and long service life

Disadvantages of Rheostat

- Large size compared to electronic controllers

- Energy loss in the form of heat

- Not suitable for low-power electronic circuits

- Mechanical wear of moving contact over time

Applications of Rheostat

Due to their ability to handle high power, rheostats are widely used in many electrical systems.

- Speed control of DC motors

- Starting and current control of large motors

- Control of welding current

- Voltage control in X-ray machines

- Heating control in electric ovens and furnaces

- Laboratory testing and experiments

- Load testing of generators

Difference Between Rheostat and Potentiometer

| Parameter | Rheostat | Potentiometer |

|---|---|---|

| Number of Terminals | Two | Three |

| Power Rating | High | Low |

| Main Use | Current control | Voltage division |

| Applications | Industrial, power circuits | Electronic circuits |

Conclusion

A rheostat is a vital electrical device used for controlling current in high-power circuits. With its simple construction, reliable operation, and ability to withstand high temperatures, it continues to be widely used in industrial and laboratory applications. Although modern electronic controllers are replacing rheostats in some areas, their robustness and simplicity still make them an important component in electrical engineering.