Plate earthing is a method of grounding electrical systems by burying a metallic plate deep into the ground to provide a low-resistance path for fault currents. This ensures the safety of electrical equipment and personnel by preventing electric shocks and minimizing voltage fluctuations.

Parts of Plate Earthing System

- Earth Plate: A copper or galvanized iron (GI) plate is used, usually measuring 600 mm x 600 mm x 3 mm for copper and 600 mm x 600 mm x 6 mm for GI.

- Earth Pit: A dugout area where the plate is buried, typically 2-3 meters deep.

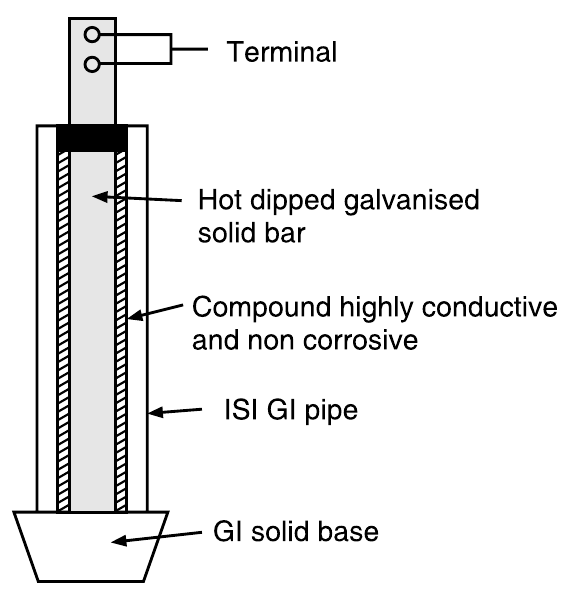

- Earthing Electrode: A conductive material that ensures contact with the soil and helps dissipate electrical energy.

- Earthing Wire: Copper or GI wire connects the plate to the electrical system.

- Moisture Retaining Material: Charcoal and salt are used to maintain soil moisture, improving conductivity.

- Watering Pipe: A GI pipe allows water to be poured into the pit to maintain moisture.

- Earth Pit Cover: A concrete or cast iron cover is used to protect the earthing setup from damage.

Procedure for Plate Earthing

- Excavation: Dig a pit of about 2-3 meters deep.

- Plate Placement: Place a copper or GI plate vertically in the pit.

- Connecting Wire: Attach the earthing wire to the plate using welding or a bolt.

- Filling with Charcoal and Salt: Surround the plate with alternate layers of charcoal and salt for moisture retention.

- Watering Pipe Installation: Place a GI watering pipe beside the plate for maintaining moisture.

- Backfilling: Cover the pit with soil to complete the setup.

- Pit Covering: Place a cover to protect the earthing pit.

- Testing: Check the resistance using an earth resistance tester to ensure effectiveness.

Advantages of Plate Earthing

- Low Resistance Path: Provides efficient grounding for electrical systems.

- Long-Lasting: With proper maintenance, plate earthing systems can last for years.

- Reliable Performance: Ensures safe dissipation of fault currents.

- Suitable for High Load Systems: Can handle large electrical loads effectively.

- Minimal Maintenance: Requires periodic watering but has low overall maintenance costs.

Disadvantages of Plate Earthing

- High Installation Cost: Requires extensive digging and materials like copper plates.

- Space Requirement: Needs a large area for effective installation.

- Soil Dependency: Effectiveness depends on soil moisture and conductivity.

- Regular Maintenance: Needs frequent watering to maintain conductivity.

Applications of Plate Earthing

- Industrial Installations: Used in factories, substations, and power plants for electrical safety.

- Commercial Buildings: Ensures safety in large office spaces.

- Residential Buildings: Protects home appliances and electrical systems.

- Telecommunication Towers: Provides grounding for communication equipment.

- Lightning Protection Systems: Used in grounding lightning arresters to prevent damage.

- Data Centers: Ensures proper earthing for sensitive electronic equipment.

Difference Between Pipe Earthing and Plate Earthing

| Feature | Pipe Earthing | Plate Earthing |

|---|---|---|

| Electrode Used | GI or Copper Pipe | GI or Copper Plate |

| Installation Depth | 2.5 to 3 meters | 2 to 3 meters |

| Maintenance | Requires less maintenance | Needs frequent watering |

| Cost | Lower compared to plate earthing | Higher due to materials and labor |

| Efficiency | Moderate | High |

Conclusion

Plate earthing is one of the most effective methods for grounding electrical systems. Although it requires careful installation and maintenance, its advantages outweigh the drawbacks, making it a preferred choice for various applications. By providing a low-resistance path to dissipate fault currents safely, plate earthing plays a crucial role in electrical safety and system reliability.