A Pitot tube is a commonly used variable head, fluid velocity measuring device. It is also called as Pitot static tube or air speed indicator (in aircraft).

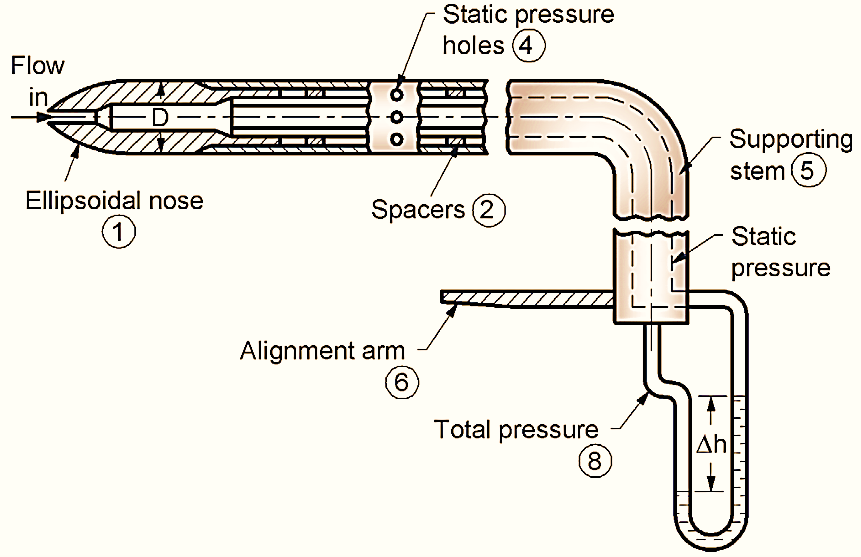

Figure 1: Pitot Tube.

A Pitot tube is a device used to measure the velocity of fluid flow, commonly used in aerodynamics and fluid mechanics applications. It measures both the total (stagnation) pressure and static pressure of the fluid to calculate its dynamic pressure and subsequently the flow velocity.

Working Principle of Pitot Tube

The Pitot tube operates on the principle of Bernoulli’s equation, which relates pressure, velocity, and height in a steady flow of an incompressible fluid. When a fluid enters the Pitot tube, it comes to rest (stagnates) at the opening of the tube, converting the kinetic energy of the fluid into pressure energy. This enables the measurement of the fluid’s velocity by comparing the total pressure with the static pressure.

Construction of Pitot Tube

A typical Pitot tube, as shown in the figure 1, consists of the following parts:

Ellipsoidal nose: The front tip of the Pitot tube that faces the fluid flow.

Spacers: Used to maintain the position and alignment of the internal parts.

Static pressure holes: Small holes on the sides of the tube, away from the flow direction, to measure the static pressure of the fluid.

Supporting stem: The structure that holds the Pitot tube in position.

Alignment arm: Ensures proper orientation of the tube in the fluid flow.

Static and Total Pressure Connections: Tubes leading to a manometer or pressure measurement system.

Δh (Delta h): Represents the difference in pressure levels, which corresponds to the dynamic pressure.

Working of Pitot Tube

- The Pitot tube is inserted into the fluid flow with its nose aligned to face the flow.

- The fluid enters the open end, where its velocity reduces to zero (stagnates). The pressure at this point is the total pressure.

- Static pressure is measured using the side holes, which are perpendicular to the flow and do not disturb it.

- The total pressure and static pressure are recorded, and the difference between them gives the dynamic pressure.

Stagnation point

When the solid body is kept centrally and stationary, in the pipe line with fluid streaming down, the velocity of the fluid diminishes due to the presence of the body still it is reduced to zero in front of the body. This is what is known as stagnation point. The inner (stagnation) tube is open ended. It faces the incoming stream of fluid.

The fluid impinging this open end is brought to rest and its kinetic energy is converted into pressure head. This pressure head is called as “Velocity head”. Thus the pressure sensed by the stagnation tube (stagnation pressure) is greater than that in the free stream by velocity head.

Stagnation pressure consists of velocity head and the static pressure head of the free stem. The static tube is closed at the nose of the tube. It has ellipsoidal head at the nose of the tube. This is the facility is to avoid flow separations. Stream lines next to the nose are longer than in the undisturbed flow. This indicates increase in the velocity.

On the other hand right angled stem stagnates the flow. It tends to raise the static pressure in its vicinity. For an accurate result the pitot tube is moved across the entire diameter of the pipe to measure the velocity at different points so that average velocity is calculated.

Working Formula of Pitot Tube

The velocity of the fluid is calculated using the relationship:

Where:

\[ v = \sqrt{\frac{2 (\Delta P)}{\rho}} \]

- : Fluid velocity (m/s)

- : Dynamic pressure (Total pressure – Static pressure) in Pascals (Pa)

- : Density of the fluid (kg/m³)

Advantages of Pitot Tube

- Simple construction.

- Less pressure loss.

- Can be inserted in the pipe very easily.

- Useful to check mean velocity of flow

Disadvantages of Pitot Tube

- Accuracy is very less.

- Not suitable for low velocity measurements (below 5 m/sec).

- Sensitive to misalignment of the probe w.r.t free stream velocity.

- Not suitable for measurement of fluctuating velocities.

- Unsuitable for dirty, sticky fluids.

- Use is limited to exploratory studies.

- Not commonly used in industrial applications.

Applications of Pitot Tube

- Useful in gas flow measurements.

- Measurements of flow through large pipes and ducts.

- Stream measurement where accuracy is not that important.