An optical pyrometer is an instrument used to measure high temperatures, often in industrial applications, by comparing the intensity of radiation emitted by a hot object to that of a calibrated light source. Unlike contact thermometers, it measures temperature without making physical contact with the object, making it suitable for measuring extreme heat such as molten metals, furnaces, or other inaccessible surfaces.

Construction of an Optical Pyrometer

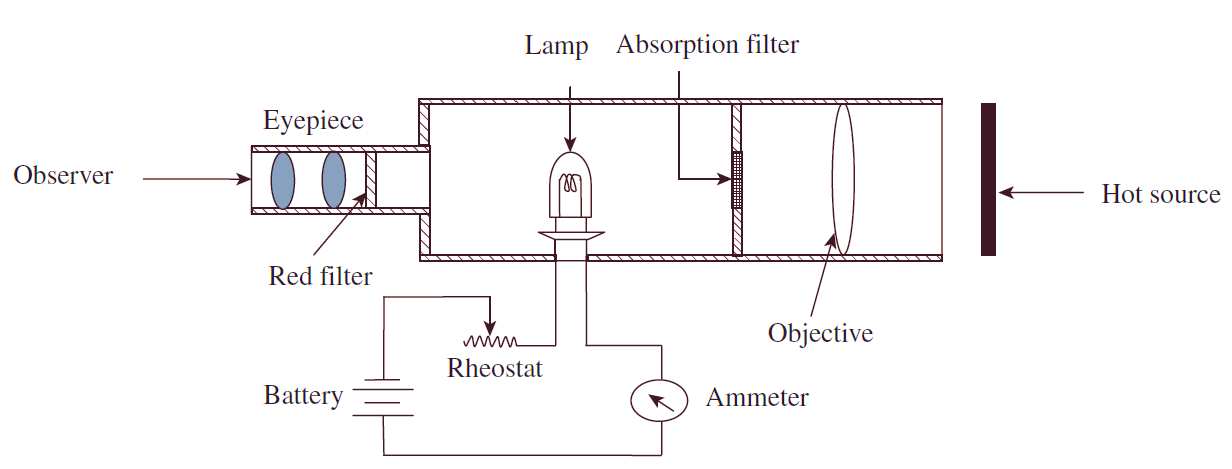

Figure 1.

The key components (see figure 1) of an optical pyrometer include:

- Eyepiece: The observer uses the eyepiece to visually align the filament of the lamp with the target object.

- Red Filter: A red filter is used to narrow the spectrum of light and enhance accuracy, allowing only specific wavelengths to pass through.

- Lamp with Filament: A tungsten filament inside the lamp is used as a reference for brightness comparison. Its brightness changes with the current passing through it.

- Absorption Filter: It ensures that the light entering the optical system matches the required wavelength range.

- Rheostat (Variable Resistor): Adjusts the current passing through the filament to control its brightness.

- Battery: Provides the power supply for the circuit.

- Ammeter: Measures the current passing through the filament, which is used to calibrate the corresponding temperature.

- Objective Lens: Focuses the radiation from the hot source onto the filament for better visibility.

- Hot Source (Target): The object whose temperature is to be measured.

Working Principle of Operation

The optical pyrometer operates based on the disappearing filament principle. This principle states that when the brightness of the filament in the optical pyrometer matches the brightness of the target, the filament visually “disappears” against the background.

The operation relies on Planck’s radiation law, which describes how the intensity of radiation emitted by an object is related to its temperature and wavelength. Hotter objects emit more intense radiation, particularly at shorter wavelengths.

Working of an Optical Pyrometer

The working process involves the following steps:

Step 1: Focus the Target – The objective lens focuses the light emitted by the hot object onto the filament. This ensures a clear view through the eyepiece.

Step 2: Adjust the Filament Brightness – Using the rheostat, the observer adjusts the current through the filament to match the brightness of the target object.

Step 3: Visual Matching – The observer looks through the eyepiece to visually compare the filament’s brightness with the target.

- If the filament appears darker than the background, the current is too low.

- If the filament appears brighter, the current is too high.

- When the filament “disappears”, its brightness matches the target object’s brightness.

Step 4: Record the Current: The current passing through the filament at the point of brightness matching is measured using the ammeter.

Step 5: Determine the Temperature: The measured current corresponds to a specific temperature, which is calibrated and displayed on the pyrometer’s scale or calculated using known calibration equations.

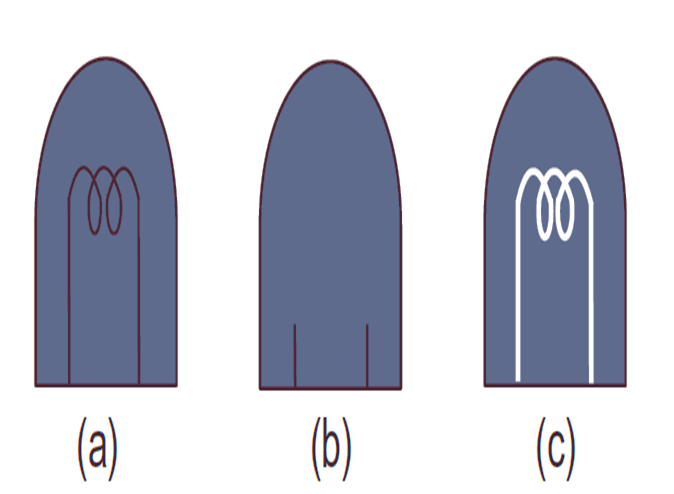

(a) Low Current: The filament appears darker than the target because its temperature (and thus brightness) is lower than the target’s.

(b) Matched Brightness: The filament “disappears” when its brightness matches the target, indicating that the current is exactly right for the corresponding temperature.

(c) High Current: The filament appears brighter than the target because its temperature (and brightness) exceeds the target’s.

Applications of Optical Pyrometers

Optical pyrometers are widely used in various industries due to their ability to measure high temperatures accurately and without contact. Some notable applications include:

- Metal Industry: Measuring the temperature of molten metals, furnaces, and heated surfaces in steel and aluminum production.

- Glass Industry: Monitoring the temperature of molten glass during manufacturing and processing.

- Power Plants: Measuring boiler temperatures, turbine blades, and other high-temperature components.

- Ceramics: Ensuring optimal temperatures during the firing and sintering processes in kilns.

- Research and Development: Conducting experiments where high temperatures need precise measurement, such as combustion research or material testing.

- Aerospace: Testing engines, turbines, and other components subjected to extreme heat.

- Automotive: Analyzing engine performance and exhaust temperatures.

Advantages of Optical Pyrometers

- Non-Contact Measurement: Allows temperature measurement of inaccessible or hazardous objects.

- High-Temperature Range: Can measure temperatures beyond the capability of conventional thermometers (e.g., up to 3000°C).

- Quick Response: Provides real-time temperature readings.

- Durability: Can withstand harsh environments without compromising accuracy.

- Wide Applicability: Suitable for industries requiring high-temperature measurements.

Limitations of Optical Pyrometers

- Dependency on Visual Observation: Requires a skilled observer to match brightness, leading to potential errors.

- Limited to Radiating Objects: Cannot measure the temperature of objects that do not emit sufficient radiation (e.g., low-temperature objects).

- Influence of Ambient Light: Bright surroundings or poor contrast may affect accuracy.

- Calibrated for Specific Wavelengths: The accuracy of measurements may depend on the type of material being measured due to its emissivity.

- Manual Adjustment: Matching brightness can be time-consuming and subjective.

Calibration and Maintenance

Calibration

Regular calibration is necessary to maintain accuracy. This involves comparing the pyrometer readings with a known standard, such as a blackbody radiator.

Maintenance

Keep the optical components clean and free of dust or smudges. Inspect the filament and circuitry periodically to ensure proper functioning.

Types of Optical Pyrometers

| Type | Features | Applications |

|---|---|---|

| Disappearing Filament Pyrometer | Compares filament brightness to the target object | Metal and glass industries |

| Infrared Pyrometer | Measures infrared radiation emitted by objects | Non-contact industrial applications |

| Multi-Wavelength Pyrometer | Accounts for emissivity variations using multiple wavelengths | High-precision temperature measurements |

| Fiber Optic Pyrometer | Uses optical fibers for confined or inaccessible areas | Aerospace and research laboratories |

Conclusion

The optical pyrometer remains an invaluable tool for measuring high temperatures in industrial and scientific applications. Its non-contact nature, wide temperature range, and precision make it indispensable in environments where conventional thermometers fail. Advances in optical and infrared technologies continue to enhance its accuracy, ease of use, and applicability in modern industries.