A capacitor start and run motor is also known as a two value capacitor run motor. The capacitor run induction motor is same as the capacitor start induction motor, where the capacitor is connected in series with the starting winding throughout its operation.

Under this condition, the motor runs as if it is a two-phase motor but with unbalanced currents. As the capacitor is connected all the time, it is selected in such a way to have longer duty cycles, generally the capacitors connected are paper or oil capacitors. They have the torques less than the capacitor start motor but higher than split phase motor. It does not require any centrifugal switch since starting winding is continuously kept in operation.

Circuit Diagram & Working of Capacitor Run Induction Motor

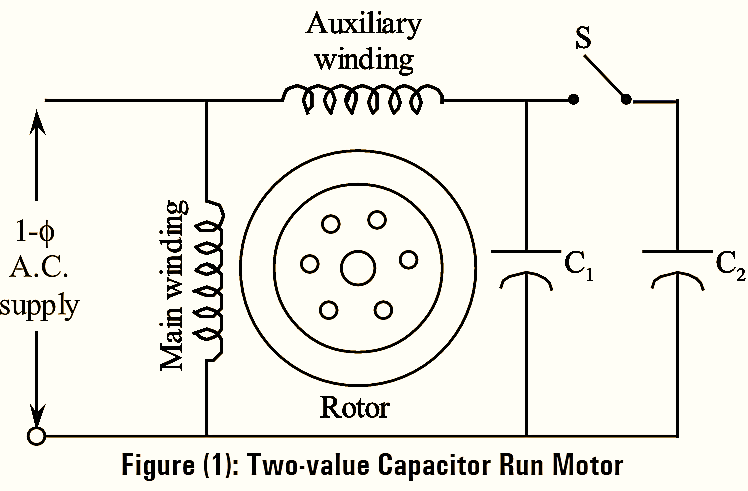

Figure (1) shows the circuit diagram of a two-value capacitor run motor supplied by single-phase supply. It consists of main winding, auxiliary winding, two capacitors C1, C2 and switch ‘S’. It is similar to the single value capacitor run motor. But the main difference here is the auxiliary winding and a capacitor C1, are always connected in the circuit. The main function of capacitor C2 is to start the motor. For this purpose, it is called the start capacitor and capacitor C1 is called the run capacitor. It improves the power factor of the motor. In general, the starting capacitor C2 is about 10 to 15 times as large as running capacitor C1. At the time of starting, the centrifugal switch ‘S’ is closed, both the capacitors C1 and C2 are in parallel and the total capacitance is the sum of their individual capacitances. After the motor reaches to 75% of the full-load speed the switch is opened and the only capacitor C1 is present in the auxiliary winding circuit. In this way, best starting performance with high capacitance and best running performance (best torque condition) with low capacitance is achieved. Such motors produce continuous torque thereby reducing the pulsating torques. By means of the two-value capacitor run motor, it is possible to obtain phase shift (β) (i.e. the angle between the currents in main winding and auxiliary winding) equal to 90º. Run capacitor C1 and auxiliary winding can be designed in such a way that they provide balanced two-phase field. The balanced two-phase field avoids the backward rotating field and improves the power factor and efficiency of the motor.

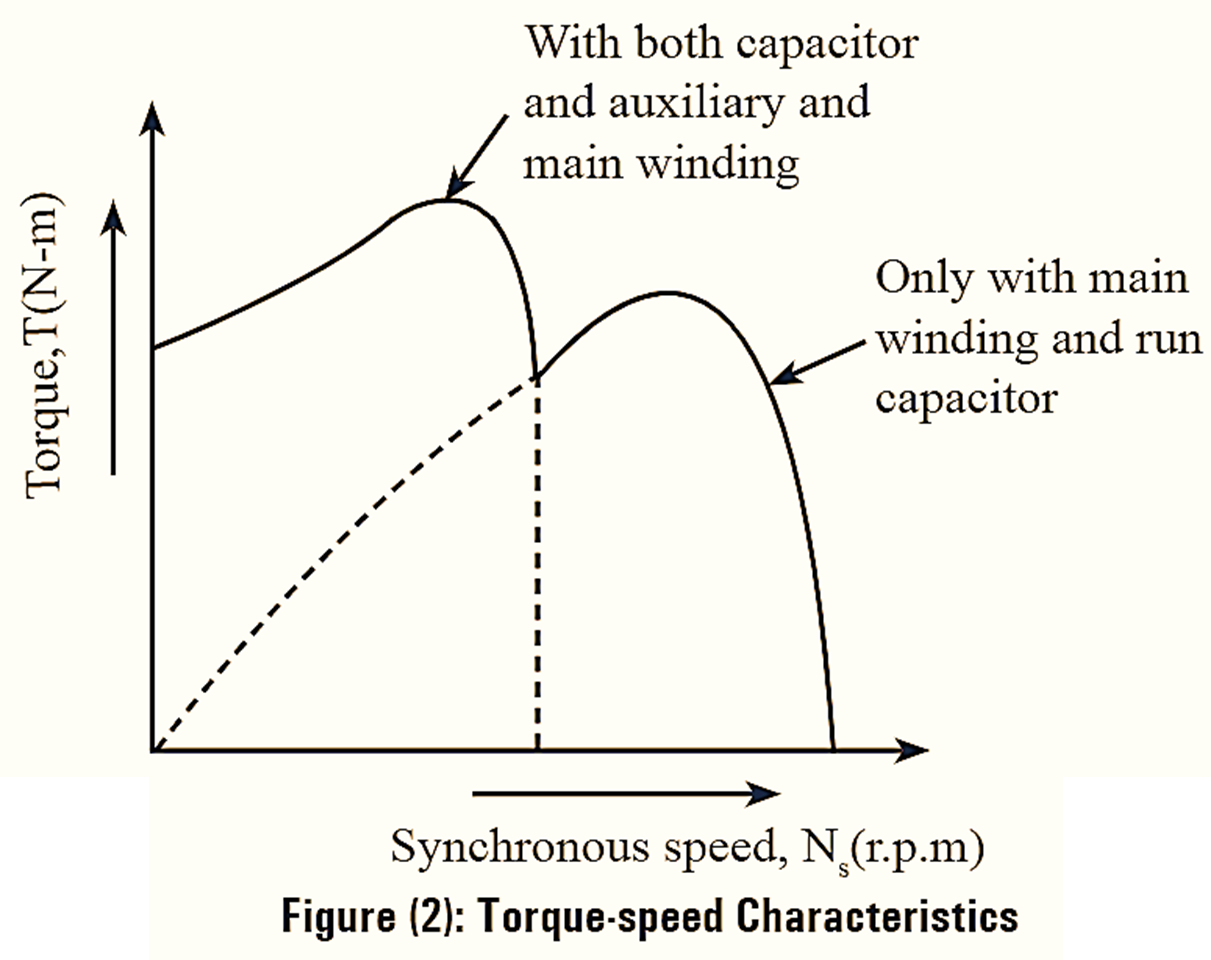

The torque-speed characteristics of two-value capacitor run motor are shown in figure (2). From the characteristics it can be observed that, when auxiliary winding is used with the main winding, improved torque is obtained.

Applications of Capacitor Run Induction Motor

These are also used in applications like pumps, compressors, refrigerators, air-conditioners, conveyors, machine tools etc.

Q 1. How can the direction of a capacitor run motor be reversed?

Ans: The direction of a capacitor run motor can be reversed by reversing the connections of start winding without disturbing the connections of run winding and vice versa. Hence, the direction of a capacitor run motor can be reversed by reversing the connections of either start or run winding but not both at the same time.