Cleat wiring is one of the oldest and simplest types of electrical wiring used in residential and industrial applications. It consists of insulated electrical wires secured on porcelain, plastic, or wood cleats that are fixed to walls or ceilings. This wiring system is mainly used for temporary installations due to its exposed design and lower durability compared to other modern wiring systems.

What is Cleat Wiring?

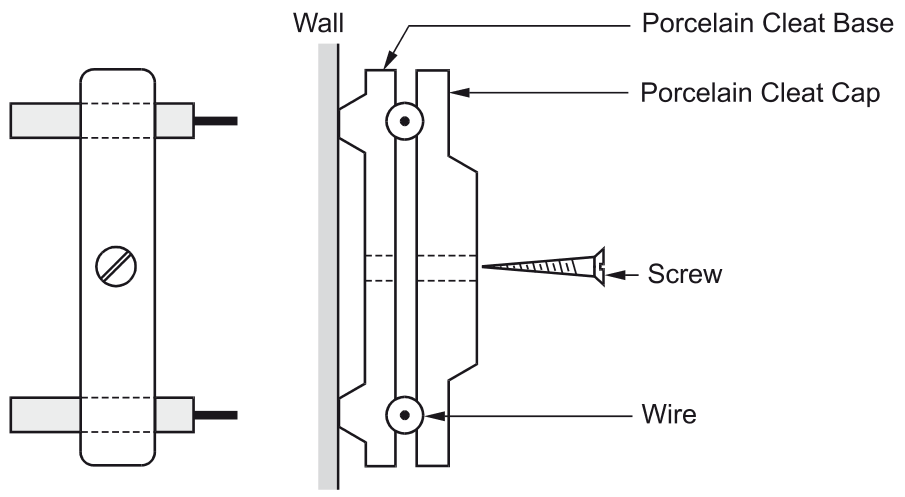

Cleat wiring is a system where PVC insulated wires or virgin insulated wires are mounted on porcelain, wood, or plastic cleats. The cleats are fixed on walls or ceilings at regular intervals using screws.

Parts of Cleat Wiring

The cleat wiring system consists of the following components:

- Porcelain Cleats (Base and Cap): The cleats are two-part fixtures, consisting of a base and a cap. The base is fixed onto the wall or ceiling, while the cap secures the wire in place. Cleats are spaced at intervals of 0.4 to 0.6 meters to hold the wires firmly.

- Electrical Wires: Typically PVC insulated wires or virgin insulated wires are used. These conductors are either single-core or twin-core depending on the requirement.

- Screws and Fixing Devices: Screws are used to attach cleats to the surface (wall or ceiling). In some cases, nails or bolts may also be used for added stability.

- Insulating Bushings: Insulating bushings are used to prevent wear and tear of wires, especially at bending points.

- Supporting Structures: The cleats are mounted on walls, ceilings, or wooden battens to ensure proper support.

Working Principle of Cleat Wiring

The working of cleat wiring is simple and follows these steps:

- Fixing the Cleats The cleats are mounted on walls or ceilings at fixed intervals using screws. The cleats should be evenly spaced (0.4 to 0.6 meters apart).

- Laying the Conductors: Insulated electrical wires are placed in the grooves of the cleats. The wires should be straight and not twisted or damaged.

- Securing the Wires: The cleat cap is placed over the wire and tightened with screws to hold the wires securely. This ensures proper insulation and prevents the wire from moving or getting damaged.

- Connection to Supply & Load: The wires are connected to electrical devices, appliances, and switches according to the circuit requirements. Fuses and circuit breakers are used for protection.

- Testing & Operation: The entire wiring system is tested using electrical testing devices to ensure there are no faults. Once tested, the circuit is switched on for operation.

Advantages of Cleat Wiring

Cleat wiring has several advantages, making it suitable for temporary and low-cost applications:

- Simple Installation: The wiring is easy to install and does not require skilled labor.

- Low Cost: Cleat wiring is cheaper compared to conduit and casing-capping wiring.

- Easy Maintenance & Repair: Faults can be easily detected and repaired without difficulty.

- Flexibility & Reusability: The wiring can be removed and reused in different locations if needed.

- Good Air Circulation: Since the wires are exposed, heat dissipation is better compared to conduit wiring.

- No Risk of Electrical Shock: The use of porcelain cleats ensures proper insulation and reduces shock hazards.

Disadvantages of Cleat Wiring

Despite its benefits, cleat wiring has several drawbacks:

- Temporary Wiring System: It is not suitable for permanent installations due to its low durability.

- Exposed to Mechanical Damage: The wires are openly mounted, making them prone to physical damage.

- Not Suitable for Damp or Harsh Environments: It is not recommended for outdoor, wet, or industrial areas where exposure to water or chemicals is common.

- Poor Aesthetic Appeal: The open wires and cleats do not provide a neat or attractive look compared to concealed wiring.

- Limited Load Capacity: Cleat wiring cannot support heavy electrical loads, making it unsuitable for large installations.

Applications of Cleat Wiring

Cleat wiring is used in the following areas:

- Temporary Electrical Installations: Construction sites, exhibition halls, and fairs where wiring needs to be temporary.

- Rural & Low-Cost Housing: Used in villages and small residential areas where cost-effective wiring is needed.

- Workshops & Agricultural Farms: Provides temporary lighting and power supply for small workshops and agricultural settings.

- Training & Educational Purposes: Used in schools and colleges for teaching electrical wiring principles.

- Testing Laboratories: Temporary setups in research and electrical testing labs.

Conclusion

Cleat wiring is a simple, economical, and easy-to-install wiring system that is mainly used for temporary electrical setups. While it has several advantages like affordability and easy maintenance, it also comes with limitations such as low durability, exposure to damage, and limited load capacity.