A Vacuum Circuit Breaker (VCB) is a type of electrical circuit breaker that interrupts current flow and isolates a circuit during faults or maintenance by extinguishing the arc in a vacuum. The vacuum serves as the arc-extinguishing medium, offering superior insulation and rapid arc suppression. VCBs are widely used in medium- and high-voltage power systems due to their reliability and efficiency.

What is Vacuum Circuit Breaker?

A Vacuum Circuit Breaker (VCB) is an electrical switching device designed to interrupt and isolate electrical circuits during faults or maintenance. It uses a vacuum as the arc-extinguishing medium, providing efficient and rapid arc suppression. The vacuum has a high dielectric strength, which makes it ideal for preventing the arc from sustaining once the current is interrupted. VCBs are commonly used in medium- and high-voltage applications, typically ranging from 11 kV to 33 kV.

Construction of Vacuum Circuit Breaker

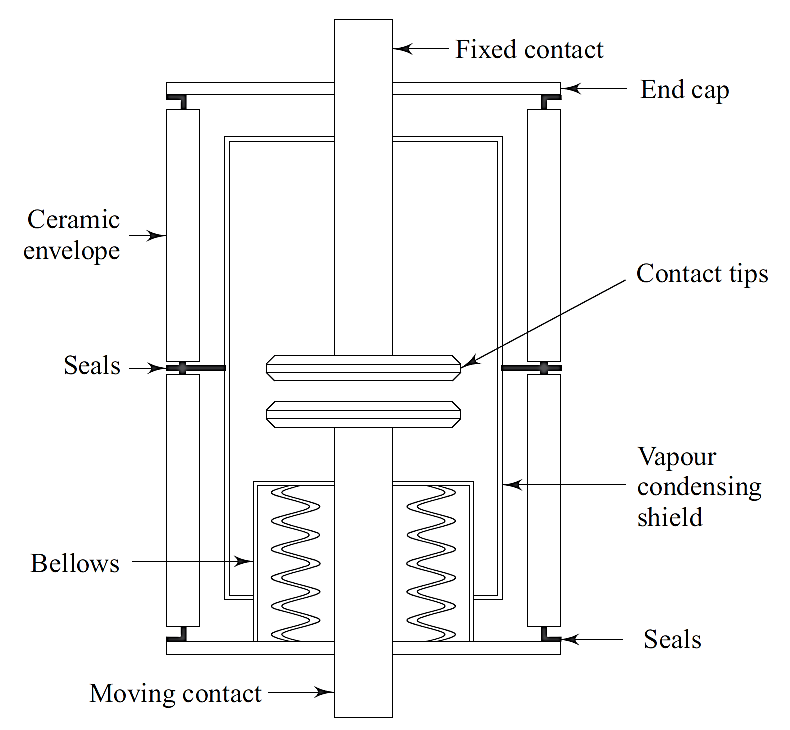

Key components of the VCB, as shown in the diagram, include:

- Fixed Contact: A stationary contact that remains fixed inside the vacuum chamber.

- Moving Contact: A contact that moves to open or close the circuit.

- Contact Tips: The actual point of contact where current passes. These tips are designed to resist wear and heat.

- Vacuum Interrupter: The core part of the breaker, which houses the contacts and operates in a vacuum environment. It consists of:

- Ceramic Envelope: Ensures high mechanical strength and insulation.

- Seals: Provide a vacuum-tight enclosure.

- Bellows: A flexible metallic component allowing the movement of the moving contact without disturbing the vacuum.

- End Cap: Seals the vacuum interrupter chamber from external contaminants.

- Vapour Condensing Shield: Captures and condenses the metal vapor generated during arcing to maintain a clean vacuum.

Working of Vacuum Circuit Breaker

- Normal Operation: Under normal operating conditions, the fixed and moving contacts remain closed, allowing current to flow through the circuit.

- Fault Condition: When a fault occurs, the breaker operates, causing the moving contact to separate from the fixed contact. This separation creates an arc between the contacts due to the ionization of metal vapors. However, the vacuum inside the interrupter has no medium to sustain the arc, leading to rapid deionization. The arc is extinguished as the metal vapors condense on the vapour condensing shield. With the arc suppressed and the contacts separated, the current flow is interrupted, effectively isolating the faulty circuit. This entire process ensures quick and efficient fault clearing, making vacuum circuit breakers reliable for high-voltage applications.

Types of Vacuum Circuit Breaker

| Type | Description |

|---|---|

| Indoor Vacuum Circuit Breaker | Used in indoor installations such as factories and substations for medium voltage systems. |

| Outdoor Vacuum Circuit Breaker | Designed for outdoor applications, typically used in substations and power distribution networks. |

| Generator Vacuum Circuit Breaker | Specially designed to handle high fault currents and protect generators. |

Advantages of Vacuum Circuit Breaker

- Efficient Arc Extinction: Vacuum quickly extinguishes the arc as there are no ionizable particles.

- Long Life: Minimal contact erosion results in extended operational life.

- Compact and Lightweight: Smaller size and lighter weight compared to other circuit breakers.

- Low Maintenance: Requires less maintenance due to the absence of oil or gas.

- Environmentally Friendly: No emission of harmful gases or oil contamination.

- Fast Operation: Quickly interrupts fault currents, enhancing safety and reliability.

Disadvantages of Vacuum Circuit Breaker

- High Initial Cost: The manufacturing process and materials used can make VCBs expensive.

- Limited to Medium Voltage: Not typically suitable for extremely high voltage (above 36 kV) without modifications.

- Contact Surface Contamination: Can result in reduced performance if the contact surfaces are not clean.

- Specialized Equipment Required: Requires specific tools and expertise for repair and maintenance.

Applications of Vacuum Circuit Breaker

- Medium-Voltage Power Systems: Widely used in industrial facilities, distribution systems, and substations.

- Power Plants: Suitable for isolating generators and transformer feeders.

- Railways and Transport Systems: Deployed in traction substations for railways and metros.

- High-Voltage Industrial Plants: Used to protect heavy equipment such as motors, transformers, and capacitors.

Conclusion

Vacuum circuit breakers are a vital component in modern electrical power systems due to their reliability, fast arc extinguishing capabilities, and minimal environmental impact. While they may have limitations in cost and voltage range, their advantages far outweigh these drawbacks in medium-voltage applications.