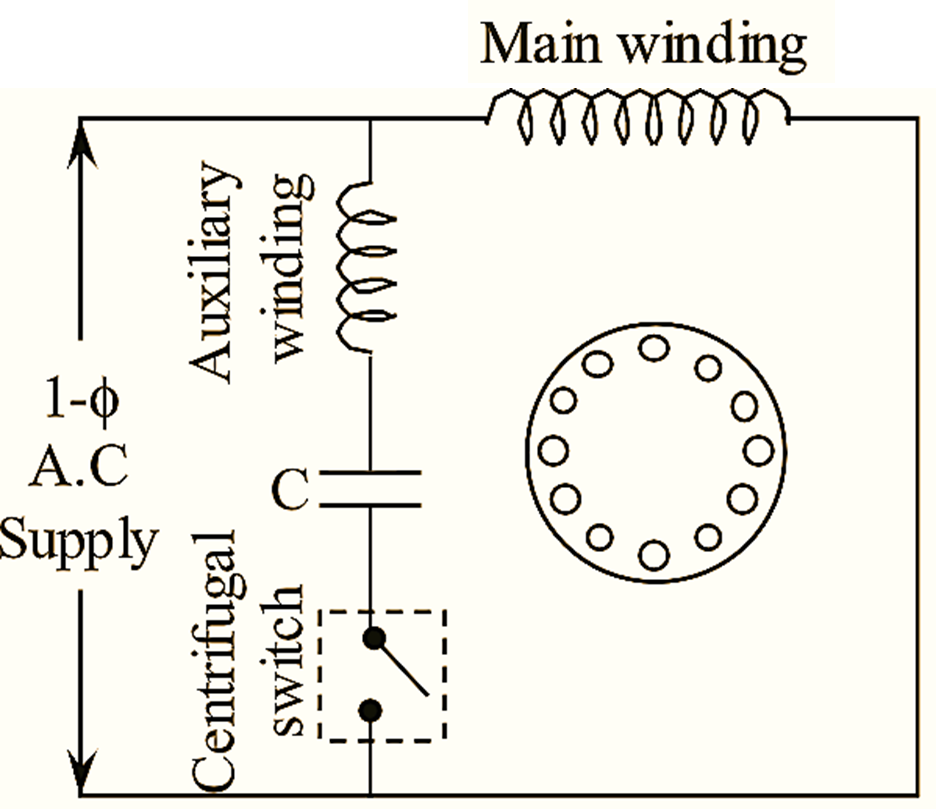

In the capacitor-start induction motor, a high value of capacitor usually electrolytic type of capacitor is connected in series with the starting winding or auxiliary winding.

Fig. 1. Capacitor Start Induction Motor.

This capacitor is designed for short duty service. The phase displacement between the two phase currents is 90º, so the starting torque developed is more (twice that of split-phase motor). A centrifugal switch is connected in series with the capacitor and the starting winding so that they could be isolated at speeds near the full-load speeds. Because of the presence of capacitor, the starting current could be in phase with the operating supply voltage. The circuit is as shown in figure (1).

Construction of Capacitor Start Induction Motor

The construction of capacitor start induction motor is almost same as that of a split phase induction motor. In this motor capacitor is connected in series with auxiliary or starting winding and are mounted on top of the motor in any convenient external position by means of metal casing, in some cases it may be mounted inside the motor. The capacitor used in this motor provide higher starting torque and limits the starting surge of current to a lower value than developed by the split phase motor.

Working of Capacitor Start Induction Motor

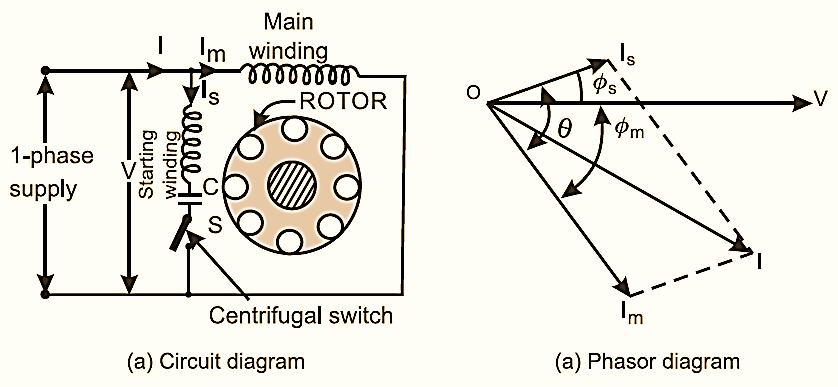

The schematic diagram of capacitor start induction motor is shown in figure 2(a). In this motor an inexpensive and small A.C electrolytic type of capacitor is connected in series with the starting winding or the auxiliary winding. So that the current through the main winding, Im lags behind the current of starting winding, IS by an θ ( approximately equal to 90º) as shown as figure 2(b). This results in high starting torque. The starting torque of a capacitor start induction motor, ranges between 3 to 4.5 times the full-load torque which is twice that of split phase induction motor. A centrifugal switch is connected in series with auxiliary winding and capacitor. The purpose of this switch is to disconnect the capacitor when motor attains 75% of full-load speed. At rated speed motor operates with main winding.

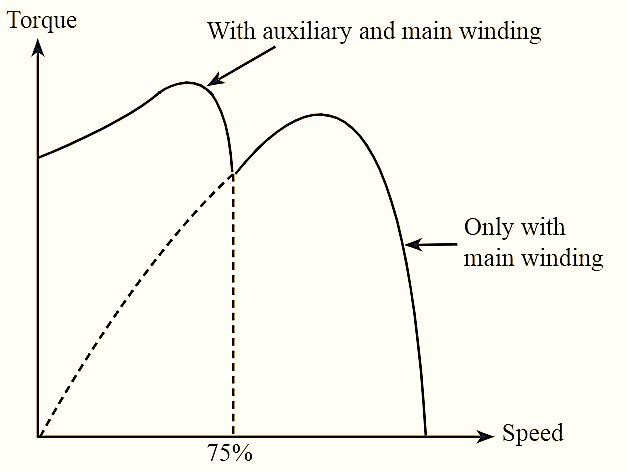

Figure 3.

The speed-torque characteristics of capacitor start induction motor are shown in figure (3). These motors are quite expensive than split phase induction motor because of the addition of capacitor.

Applications of Capacitor Start Induction Motor

- Due to high starting torque, capacitor start induction motors are used for high inertia loads and also where regular starts are needed.

- These are also used in applications like pumps, compressors, refrigerators, air-conditioners, conveyors, machine tools etc.

Q1. List out the characteristic features of single-phase capacitor start motor.

Ans: The characteristic features of single-phase capacitor start motors are as follows.

- Capacitor start motors can be used for dual voltage ratings.

- They can also be used in applications where starting torque requirement is high.

- They have two windings i.e., start and run winding. When motor is started both the windings are energized but when motor attains 75% of full load speed, start winding and capacitor are disconnected from the circuit by a centrifugal switch.

Q2. How can the direction of rotation of the capacitor-start motor be reversed?

Ans: The direction of rotation of capacitor start motor can be reversed by interchanging the connections of starting winding without disturbing the capacitor connections. The direction of motor can be reversed only before the starting operation of the motor i.e., when the motor is at rest and the centrifugal switch is in closed position. Because once the motor comes in normal operating condition it will be running as single phase induction motor and at this moment the reversal of motor is attempted, then there will be no effect on the direction of rotation as centrifugal switch will be in open position and the developing torque will be in the direction of rotation.