A suspension insulator is a type of electrical insulator used in overhead power transmission and distribution lines. Its primary function is to insulate the conductor (carrying high voltage) from the supporting structure (e.g., towers or poles) and maintain the mechanical strength required to sustain the conductor.

Construction of Suspension Insulator

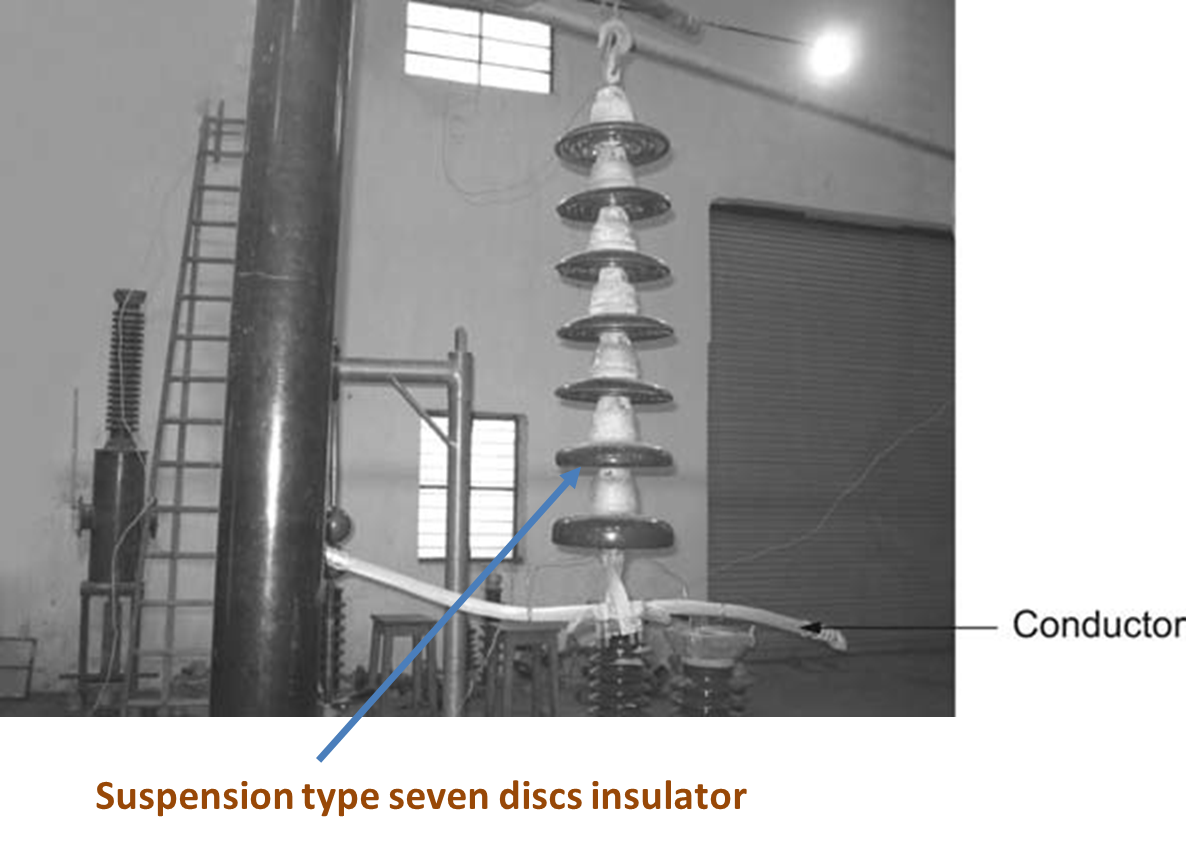

Fig. 1: Suspension Insulator.

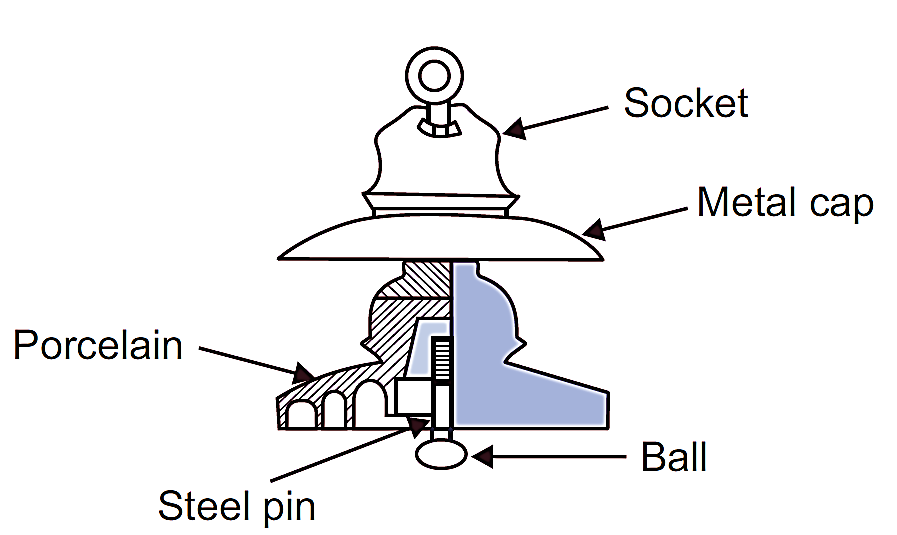

- Porcelain or Glass Body: The insulator is typically made of porcelain or toughened glass, offering excellent insulating properties and resistance to environmental factors.

- Metal Cap and Pin:

- Metal cap: Fixed at the top, it connects the insulator to the supporting structure via a hook or clamp.

- Steel pin: Located at the bottom, it connects the conductor to the insulator.

- Ball and Socket Joint: The ball-and-socket assembly allows flexibility and absorbs mechanical stresses.

- Series Construction: For higher voltages, multiple suspension insulator units are connected in series to form a string. Each unit is rated for a specific voltage (e.g., 11 kV).

Working Principle of Suspension Insulator

The suspension insulator is designed to provide:

- Electrical Insulation: Preventing current leakage through the supporting tower or pole.

- Mechanical Support: Bearing the weight of the conductor and any additional mechanical stresses, such as wind or ice loads.

Each disc of the suspension insulator is made to withstand a specific voltage (e.g., 11 kV). For high-voltage applications, multiple discs are connected in series, forming an insulator string. The string’s total voltage capacity equals the number of discs multiplied by the voltage rating of a single disc.

Working of Suspension Insulator

The suspension insulator works by preventing the flow of electric current from the live conductor to the grounded supporting structure. Here’s how it functions in detail:

Step-by-Step Working of Suspension Insulator

- Connection and Suspension: The insulator string is suspended from the cross-arm of the tower using a metal cap at the top. The conductor is attached to the bottom-most steel pin or ball.

- Voltage Distribution Across Discs: When a high voltage is applied, the discs in the string divide the voltage equally. For instance, in a 132 kV line with 12 discs, each disc will handle about 11 kV. However, due to capacitive effects, the voltage across the discs may not be perfectly uniform, with the top disc (nearest the tower) often experiencing a higher voltage than the bottom discs.

- Electrical Insulation: The porcelain or glass body prevents current leakage from the conductor to the grounded tower.

- Mechanical Flexibility: The ball-and-socket design provides flexibility, allowing the string to sway with wind and other external forces without breaking.

- Handling Overvoltages: During a surge (e.g., lightning), the string resists flashover unless the voltage exceeds its design limit. If flashover occurs, it provides a controlled path for the current, protecting the conductor and tower.

- Leakage Current Control: The design ensures minimal leakage current. Insulator surfaces are shaped to allow rain and contaminants to flow off, reducing the risk of short circuits.

Types of Suspension Insulator

Suspension insulators come in two main types based on their design:

- Cap-and-Pin Type

- Interlink Type.

Below is a tabular form differnces of both types:

| Aspect | Cap-and-Pin Type | Interlink Type |

|---|---|---|

| Connection Type | Ball-and-socket joint (cap and pin). | Metal links or interlocking rods. |

| Flexibility | Highly flexible; adapts to dynamic loads. | Less flexible; more rigid connection. |

| Ease of Maintenance | Easier to replace damaged units. | Requires more effort to replace parts. |

| Mechanical Strength | Moderate mechanical strength. | Higher mechanical strength. |

| Applications | General-purpose transmission lines. | Heavy-duty applications (long spans, extreme loads). |

Advantages of Suspension Insulators

- Flexibility: Allows easy adjustment of the number of insulator discs based on the voltage level.

- Ease of Maintenance: If a single unit gets damaged, only that disc needs to be replaced.

- High Mechanical Strength: Suitable for long spans and areas with strong winds.

- Protection from Flashover: The string configuration ensures high resistance to flashover during voltage surges.

Disadvantages of Suspension Insulators

- Space Requirements: Requires more vertical clearance compared to other insulator types.

- Cost: Initial installation can be costlier due to the need for multiple discs.

- Complexity: Assembly and alignment of multiple units can be challenging.

Applications of Suspension Insulators

- High Voltage Transmission Lines: Widely used in high-voltage AC and DC transmission systems.

- River Crossings: Where longer spans and higher mechanical strength are required.

- Electrified Railways: To insulate overhead catenary systems from supporting structures.

- Switchyards and Substations: For equipment insulation and connections.

Key Considerations for Suspension Insulators

- String Efficiency: The voltage distribution along the string is not always uniform. To improve efficiency, the top disc is sometimes made larger or grading rings are used to equalize voltage.

- Environmental Factors: Dust, pollution, and moisture can cause leakage currents or flashover. Regular cleaning or using coated insulators can help mitigate these effects.

- Failure Protection: If one disc fails, the remaining discs continue to provide insulation, preventing a catastrophic failure.

Related Posts

- What is Underground Cable? Construction, Types, Advantages, Disadvantages & Applications

An underground cable is a type of electrical cable used for transmitting and distributing electricity…

- What is Rotameter? Working Principle, Diagram, Construction, Advantages & Applications

In rotameter, the area of flow is measured in such a way that the head…

- What is Electrical Insulator? Definition, Types & Properties

Figure 1: Electrical Insulator. An electrical insulator in an overhead line is to hold the…

- What is an Autotransformer? Working Principle, Construction, Types & Applications

Unlike two winding transformer, an auto-transformer contains only one winding. This single winding serves the…

- What is an Energy Meter? Working, Diagram, Construction, Advantages, Types & Applications

An Energy Meter, also known as a watt-hour meter, is an electrical device used to…