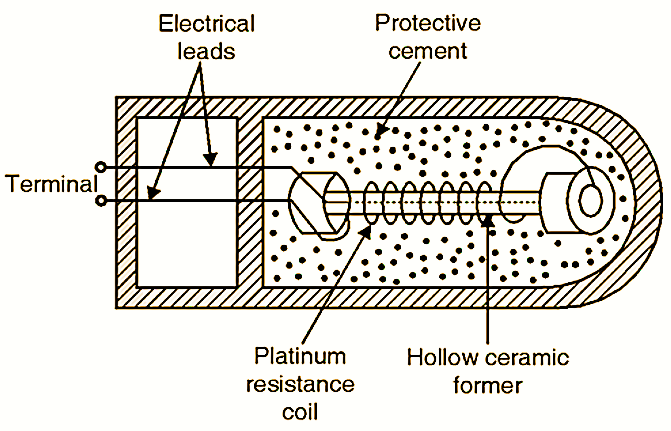

Figure 1: Resistance Temperature Detector.

Working Principle of Resistance Temperature Detector (RTD)

Resistance Thermometers or Resistance Temperature Detector (RTD) works on the principle of positive temperature coefficient of resistance. i.e. as temperature increases, resistance offered by thermometer also increases.

Working & Construction of Resistance Temperature Detector (RTD)

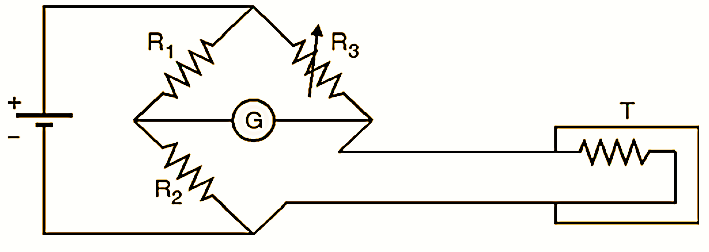

Figure 2.

Various methods are employed for construction of resistance thermometers, depending on the application. Two common types are shown in Figs. 1 and 2. The resistance of wire at tºC is given by

Rt = R0 [ 1 + α0t ]

Where,

Rt = Resistance at t°c

R0 = Resistance at 0°C

α0 = Resistance temperature coefficient

t = Change in temperature.

Modern platinum resistance thermometer.

It consists of pure, well-annealed platinum wire wound on thin strip of insulting mica or ceramic and placed in porcelain sheath. Free ends of platinum wire are attached to long lead low resistance copper wires (see Figure 1).

To measure the change in resistance bridge network is used. The resistance thermometer is connected to one of the arm of Wheatstone bridge circuit when resistance thermometer is subjected to temperature variation, the Wheatstone bridge gets unbalanced.

The galvanometer deflection can be directly calibrated to give temperature. The unknown temperature t is given as,

\[t=\frac{{{R}_{t}-{R}_{0}}}{{{{R}_{100}-{R}_{0}}}}\times 100\]

Where,

Rt Resistance of wire at temperature t

R0 = Resistance of wire at 0°C

R100 = Resistance of wire at 100°C

Measurement of the change in resistance is usually made using a wheatstone bridge. The pyrometer coil is made one arm of the bridge as shown in Fig. 2. The resistance R3 is adjusted until the meter G shown no current. Then it can be shown that,

\[\frac{{{R}_{1}}}{{{{R}_{2}}}}=\frac{{{R}_{3}}}{{{T}}}\]

For industrial use the resistance is unchanged and changes in the pyrometer resistance T cause an out of balance current to now through the meter G.

Advantages of Resistance Temperature Detector (RTD)

- The response time compared to thermocouples is very fast. In the order of fractions of a second.

- An RTD will not experience drift problems because it is not self-powered.

- Within its range it is more accurate and has higher sensitivity than a thermocouple.

- In an installation where long leads are required, the

- RTD does not require special extension cable.

- Unlike thermocouples, radioactive radiation (beta, gamma and neutrons) has minimal effect on RTDs since the parameter measured is resistance, not voltage.

Disadvantages of Resistance Temperature Detector (RTD)

- Because the metal used for a RTD must be in its purest form, they are much more expensive than thermocouples.

- In general, an RTD is not capable of measuring as wide a temperature range as a thermocouple. A power supply failure can cause erroneous readings.

- Small changes in resistance are being measured, thus all connections must be tight and free of corrosion, which will create errors.

Applications of Resistance Temperature Detector (RTD)

- Among the many uses in a nuclear station, RTDs can be found in the reactor area temperature measurement and fuel channel coolant temperature.