A Pirani Gauge is a type of thermal conductivity gauge used to measure low vacuum pressures. It operates based on the principle that the thermal conductivity of gases changes with pressure. This gauge is widely used in vacuum technology due to its simplicity and reliability in measuring pressures from 0.5 Torr to 10-4 Torr.

Construction of Pirani Gauge

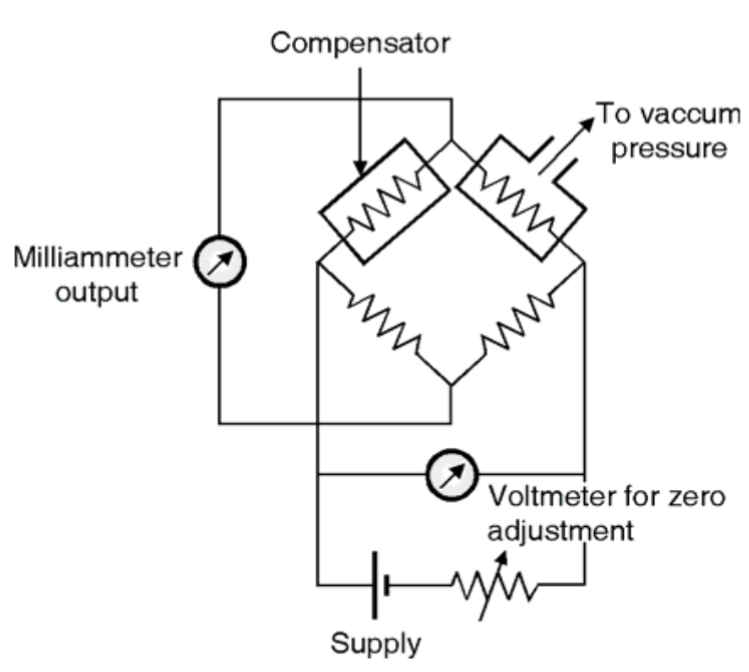

The Pirani gauge consists of the following key components:

- Sensing Element (Filament): A fine metal wire (usually platinum or tungsten) acts as a resistive element that gets heated when current passes through it.

- Wheatstone Bridge Circuit: The sensing filament is part of a Wheatstone bridge circuit to measure resistance changes accurately.

- Compensator: Another similar filament is placed in a reference chamber (sealed at a known pressure) to compensate for environmental variations.

- Vacuum Chamber Connection: The filament is exposed to the vacuum environment where pressure measurement is required.

- Power Supply & Measurement System: The circuit includes a power source, a voltmeter for zero adjustment, and a milliammeter for output measurement.

Working Principle of Pirani Gauge

The operation of a Pirani gauge is based on the change in heat loss due to gas conduction at different pressures. The sequence of operations is as follows:

- Heating the Filament: A fine wire is heated using a small electrical current.

- Heat Dissipation: The filament loses heat through conduction to surrounding gas molecules. At higher pressures, more molecules interact with the filament, increasing heat loss. At lower pressures, fewer molecules interact, reducing heat loss.

- Resistance Change Measurement: The resistance of the filament changes as its temperature changes due to varying heat dissipation.

- Bridge Circuit Response: The Wheatstone bridge circuit detects this resistance change and converts it into an electrical signal that corresponds to the vacuum pressure.

- Calibration and Readout: The output is calibrated to display pressure readings in appropriate units.

Advantages of Pirani Gauge

The Pirani gauge has several advantages:

- Wide Pressure Range: Effective in measuring vacuum pressures from 0.5 Torr to 10-4 Torr.

- Fast Response Time: Provides quick readings due to the rapid thermal response of the filament.

- Compact and Simple Design: Requires minimal components, making it easy to install and maintain.

- No Moving Parts: Enhances reliability and durability.

- Cost-Effective: More affordable compared to other high-vacuum measurement devices.

Disadvantages of Pirani Gauge

Despite its advantages, the Pirani gauge has some limitations:

- Limited Accuracy: Affected by variations in gas composition and external temperature changes.

- Filament Sensitivity: The fine filament can burn out if exposed to high pressures or reactive gases.

- Calibration Drift: Requires frequent recalibration for accurate readings.

- Dependency on Gas Type: Works best with non-reactive gases; different gases have different thermal conductivities.

Applications of Pirani Gauge

The Pirani gauge is widely used in various industries, including:

- Vacuum Systems Monitoring: Used in vacuum pumps, chambers, and industrial vacuum processing.

- Semiconductor Manufacturing: Ensures proper vacuum conditions in microelectronics fabrication.

- Space Simulation Chambers: Helps simulate outer space conditions for satellite testing.

- Research Laboratories: Used in physics and materials science experiments requiring vacuum conditions.

- Medical Equipment: Used in vacuum-based applications like freeze-drying.

- Gas Leak Detection: Helps monitor and detect vacuum leaks in sensitive equipment.

Conclusion

The Pirani Gauge is a crucial instrument in vacuum measurement, known for its simplicity, affordability, and effectiveness in a wide range of applications. Despite some limitations, it remains a widely used device in scientific, industrial, and research applications requiring precise vacuum monitoring.