An Oil Circuit Breaker (OCB) is a type of circuit breaker that uses insulating oil as both an arc-quenching medium and an insulating medium. The oil is vaporized during the interruption process, producing gases that effectively cool and extinguish the arc formed when contacts separate under load or fault conditions. It is widely used in high-voltage and medium-voltage systems.

Types of Oil Circuit Breakers

| Type | Description | Applications |

|---|---|---|

| Bulk Oil Circuit Breaker | Uses a large quantity of oil for both arc extinction and insulation. | High-voltage systems (up to 220 kV). |

| Minimum Oil Circuit Breaker | Uses a small amount of oil primarily for arc quenching, with separate insulation. | Medium-voltage systems and compact installations. |

Bulk Oil Circuit Breaker

A Bulk Oil Circuit Breaker (BOCB) is a type of circuit breaker that uses a large quantity of insulating oil for arc extinction and insulation purposes. It is one of the earliest types of circuit breakers used in power systems for medium- and high-voltage applications. In a BOCB, the oil serves a dual purpose:

- It acts as the arc-quenching medium to extinguish the arc formed during the breaking of current.

- It provides insulation between the live components and the grounded metal parts of the circuit breaker.

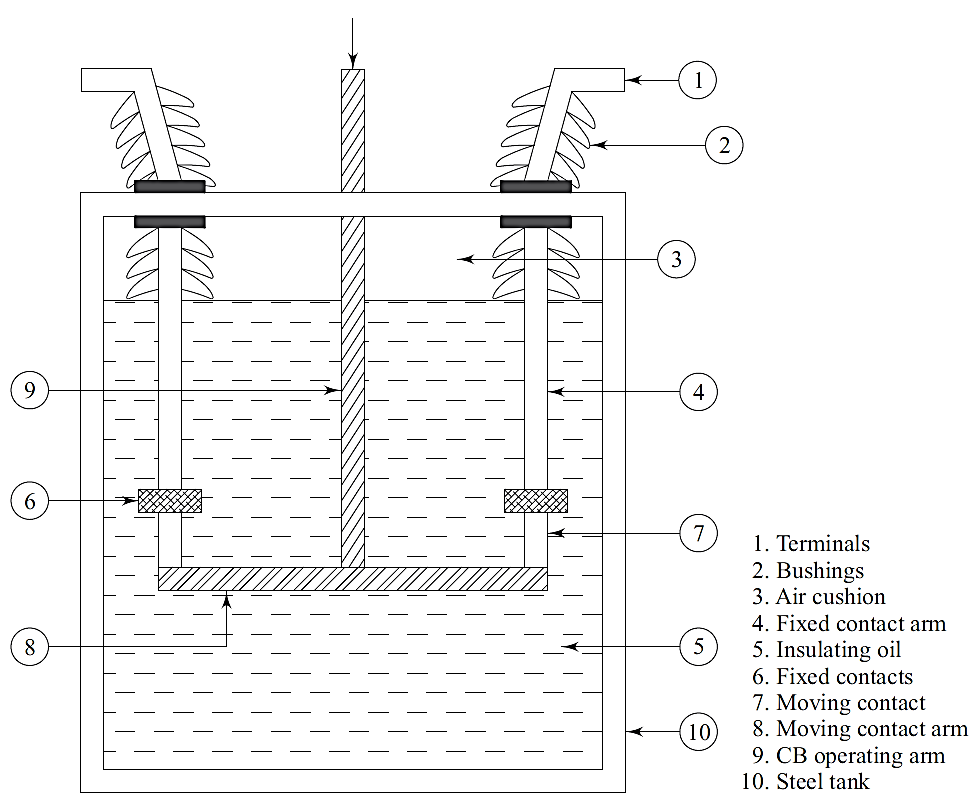

Figure 1: Oil Circuit Breaker.

Construction of Bulk Oil Circuit Breaker

This Figure 1 depicts the construction of an Oil Circuit Breaker (OCB). Below is a brief description of its key components:

- Terminals: These provide external electrical connections for the circuit breaker.

- Bushings: Insulated passages that allow the current to pass through the tank while preventing oil leakage.

- Air Cushion: Space left at the top of the tank for oil expansion and to accommodate arc gases.

- Fixed Contact Arm: A stationary component that is part of the contact assembly.

- Insulating Oil: Acts as a medium for arc quenching and provides electrical insulation.

- Fixed Contacts: These remain stationary and form part of the electrical contact during operation.

- Moving Contact: A component that moves to make or break the circuit.

- Moving Contact Arm: The arm to which the moving contact is attached and operated.

- Circuit Breaker (CB) Operating Arm: Mechanism used to operate the moving contact.

- Steel Tank: A sturdy enclosure that houses all internal components and contains the insulating oil.

Working of Bulk Oil Circuit Breaker

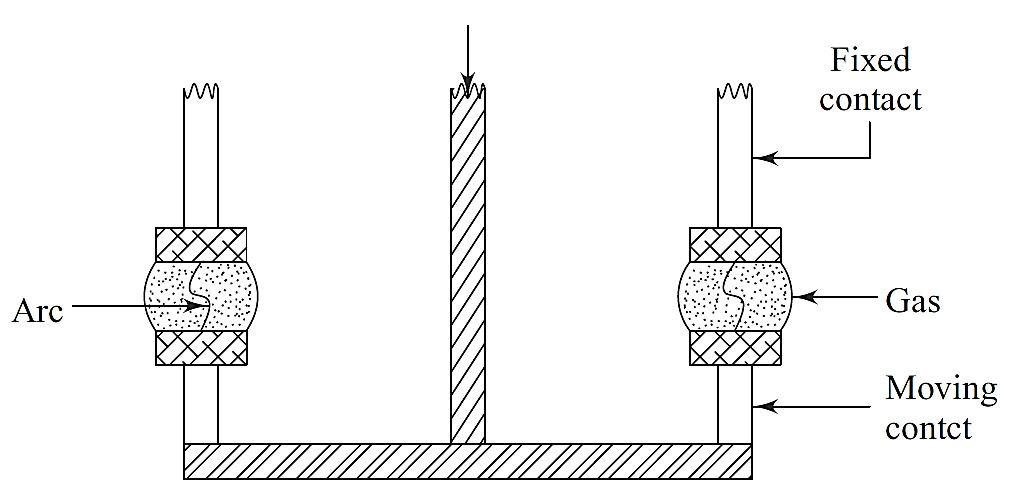

Figure 2.

This Figure 2 illustrates the working principle of an Oil Circuit Breaker (OCB) during the interruption of an electrical circuit. Here’s how it operates:

-

- Normal Operation: The fixed and moving contacts are closed, allowing current to flow through the circuit. Insulating oil acts as a dielectric medium and provides electrical insulation between components.

- Fault Condition: When a fault occurs, the circuit breaker operating mechanism separates the moving contact from the fixed contact. As the contacts separate, an arc forms between them.

- Arc Formation: The arc heats the surrounding insulating oil, causing it to vaporize and decompose. This decomposition produces hydrogen gas and other hydrocarbon gases, which are highly effective in arc quenching.

- Arc Quenching: The high-pressure gas flow generated by the vaporized oil blasts through the arc. This cools the arc, stretches it, and ultimately extinguishes it.

- Post-Operation: After the arc is extinguished, the circuit is fully interrupted. The insulating oil regains its dielectric properties and insulates the contacts.

Minimum Oil Circuit Breaker (MOCB)

A Minimum Oil Circuit Breaker (MOCB) is a type of circuit breaker that uses a reduced amount of oil as the insulating and arc-extinguishing medium. Unlike bulk oil circuit breakers, where oil serves as both the arc-quenching medium and insulation for the entire system, an MOCB confines the oil usage to the interruption chamber alone. This makes it more compact and efficient.

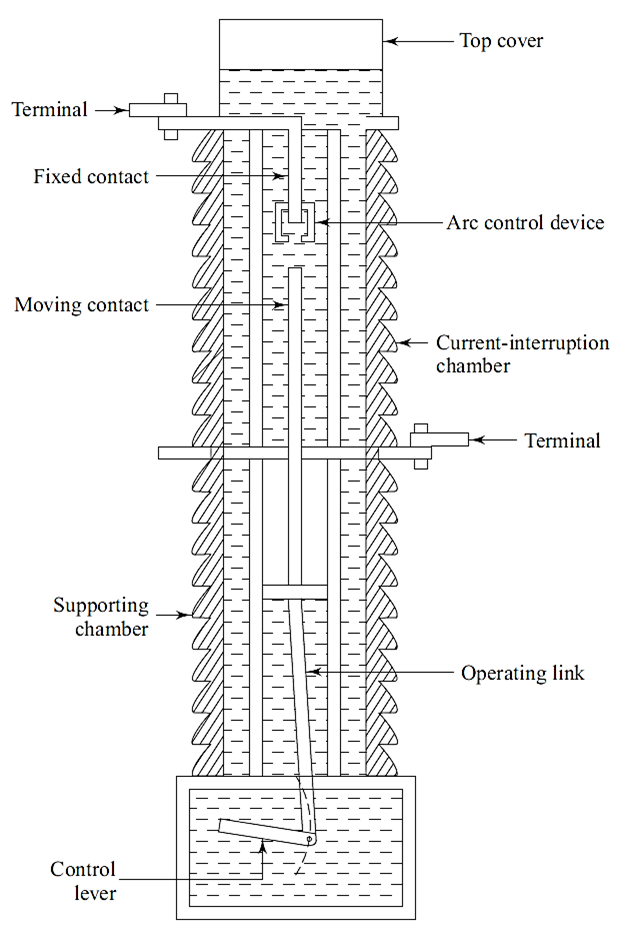

Parts of a Minimum Oil Circuit Breaker

- Top Cover: Encloses the circuit breaker and helps maintain the oil inside the chamber.

- Terminal: Connects the breaker to the external electrical circuit.

- Fixed Contact: Stationary part of the contact assembly where current flows during normal operation.

- Moving Contact: Moves to create or break the connection with the fixed contact.

- Arc Control Device: Ensures efficient quenching of the arc by cooling and splitting it into smaller arcs.

- Current-Interruption Chamber: Contains the contacts and arc control device, surrounded by oil for arc quenching.

- Supporting Chamber: Provides structural support to the breaker components and insulation from the surroundings.

- Operating Link: Transmits mechanical force from the control lever to the moving contact.

- Control Lever: Operated manually or automatically to open or close the breaker.

Working Principle of Minimum Oil Circuit Breaker

- Normal Operation: The moving and fixed contacts are closed, allowing current to flow through the breaker.

- Fault Condition: When a fault occurs, the control lever operates the operating link, causing the moving contact to separate from the fixed contact.

- Arc Formation: As the contacts separate, an arc forms between them. The heat from the arc decomposes the oil, generating hydrogen gas.

- Arc Quenching: The arc control device splits the arc into smaller segments. The hydrogen gas generated by the vaporized oil surrounds the arc and extinguishes it effectively.

- Insulation: The remaining oil acts as an insulating medium to prevent a short circuit between the contacts.

Advantages of Oil Circuit Breakers

- Efficient Arc Quenching: The vaporized oil generates hydrogen gas, which has excellent arc-extinguishing properties.

- High Dielectric Strength: The insulating oil provides good electrical insulation between live parts and the earth.

- Compact Design: The combination of arc-quenching and insulating properties in one medium makes OCBs relatively compact.

- Reliable Performance: OCBs can handle high-current interruptions effectively and are suitable for both outdoor and indoor installations.

- Cost-Effective: Compared to some modern alternatives, OCBs are less expensive in initial investment.

Disadvantages of Oil Circuit Breakers

- High Maintenance Requirement: The insulating oil deteriorates over time due to carbon deposits and contamination, requiring regular replacement or purification.

- Risk of Fire or Explosion: The insulating oil is flammable, posing safety risks in case of a fault or equipment failure.

- Slow Operation: OCBs have a slower response time compared to modern vacuum or SF₆ circuit breakers.

- Environmental Concerns: Disposal of used oil poses environmental challenges and requires compliance with regulations.

- Large Oil Volume: Handling large quantities of oil can increase operational and maintenance complexities.

Applications of Oil Circuit Breakers

- Power Transmission and Distribution: Widely used in substations for interrupting high-voltage circuits.

- Industrial Power Systems: Employed in industries to protect equipment and machinery from fault currents.

- Rural Electrification: Suitable for remote areas due to their cost-effectiveness and reliable performance.

- Backup Systems: Used as backup protection in power grids and generator systems.