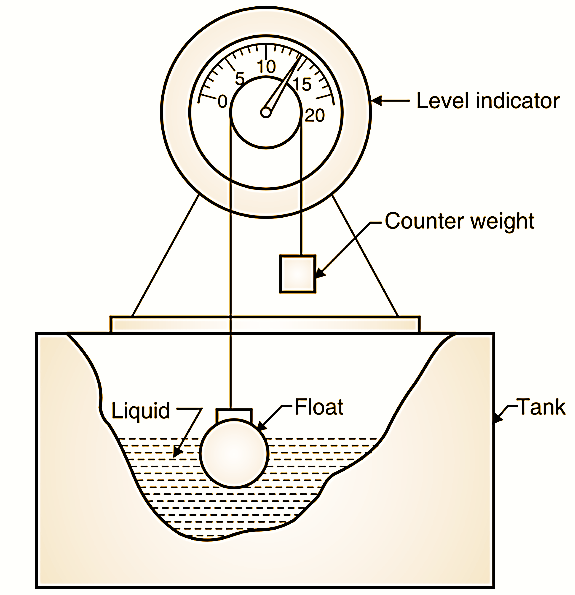

Figure 1: Float Level Sensor.

Working and Construction of Float Level Sensor

The float type level indicator is shown in Fig. 1. A float rests on the surface of liquid and follows the changing level of liquid. The movement of the float is transmitted to the pointer by a stainless steel or phosphor-bronze flexible cable wound around a pulley, and the pointer indicates liquid level in the tank. The float is made is made of corrosion resisting material and it rests on liquid level surface between two grids to avoid error due to turbulence. With this type of instrument, liquid level from 1/2 ft. to 60 ft. can be easily measured.

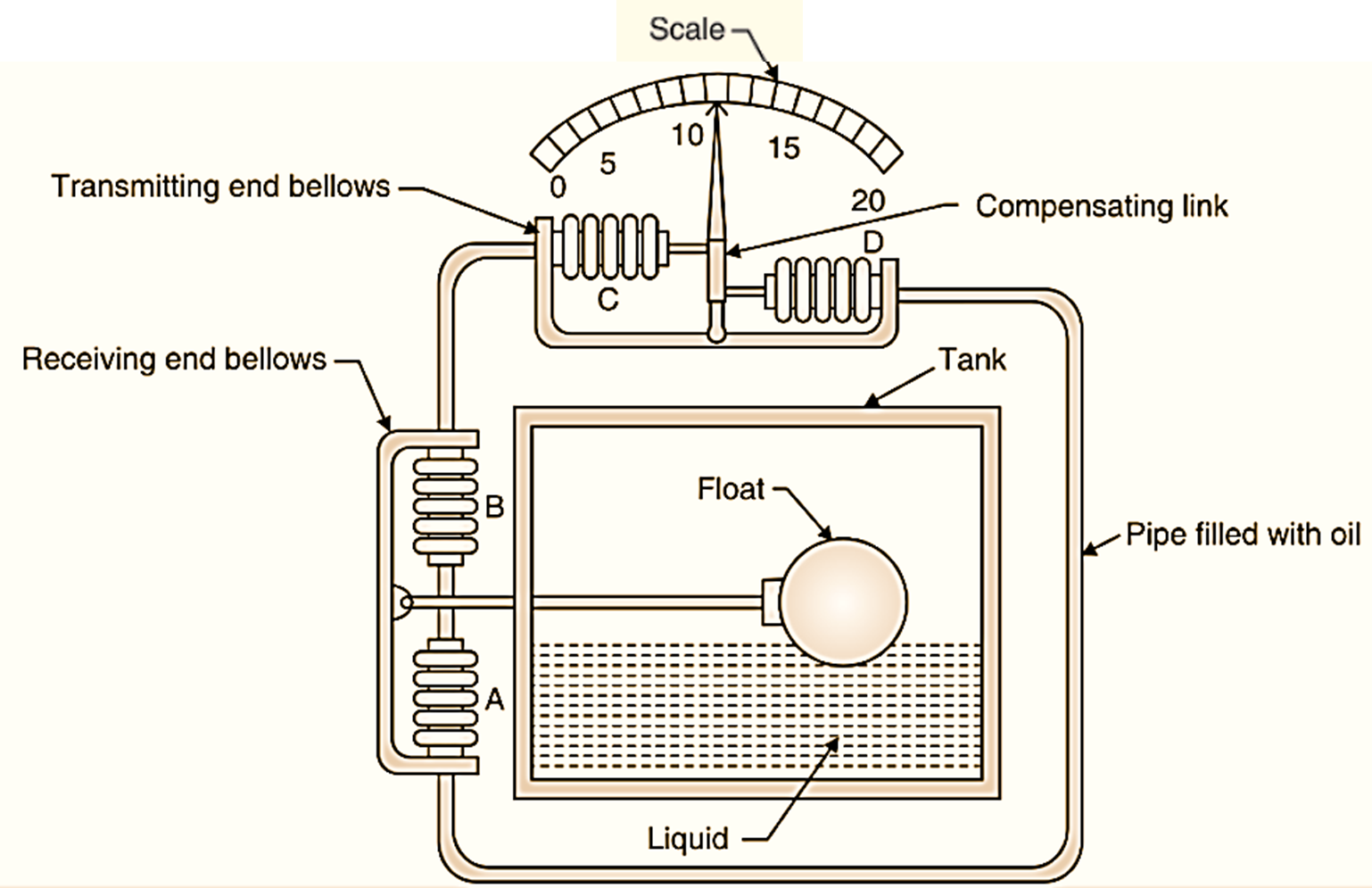

Figure 1: Hydraullic Transmission system for level indicator.

The liquid level can be transmitted to a distant place using a hydraulic transmission system as shown in Fig.1. It consists of four bellows elements, two on the transmitter side (C and D) and two on the receiver side (A and B) and are fixed at the outer ends.

Bellows B, C and A, D are hydraulically connected through pipes filled with an oil. When the float moves up or down according to change in level, its position is transmitted by a lower arm to the bellows assembly A – B.

When the level rises, B is compressed and A expands, thus causing oil in the pipe to flow from B to C, and from D to A. The bellows are balanced so that the movement at the transmitter end is reproduced in reverse made at the receiving end i.e. C expands and D is compressed as the liquid level rises.

The two bellows C and D act on the compensating link pivoted on the pointer, in the same directions and will rotate the pointer in proportion to the level value. Any change in ambient temperature affects both the bellows i.e. both expand or contract. Therefore level transmissions at the pointer is not affected with this type of instrument level transmission up to 250 ft. can be achieved.

Advantages of Float Level Sensor

- Possible to read liquid levels, in a tank from ground level even if the tank is kept below the ground level.

- Low cost.

- Large temperature range.

- Reliable design.

- Possible to make it using corrosion-resistant material.

Disadvantages of Float Level Sensor

- Limited to moderate pressure.

- Tailored to tank geometry.