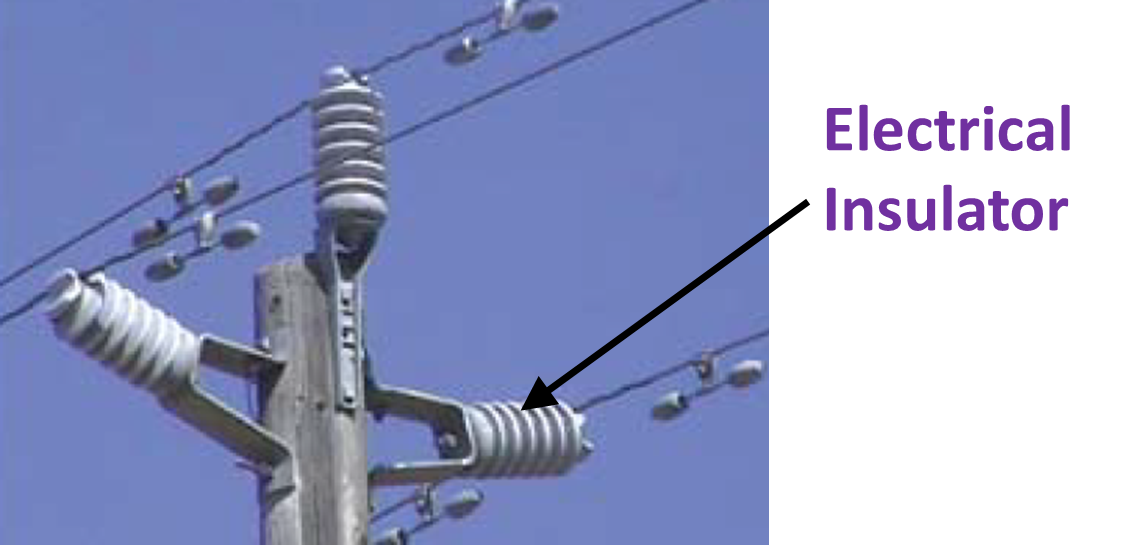

Figure 1: Electrical Insulator.

An electrical insulator in an overhead line is to hold the live conductor to prevent leakage of current from the conductor to the pole. These are made of porcelain clay and are thoroughly glazed to avoid the absorption of moisture from the atmosphere.

Properties of an Electrical insulator

- It should have high electrical resistance in order to prevent the leakage of current.

- It should have high mechanical strength in order to withstand the weight of conductor and the forces acting due to wind pressure, ice etc.

- It should have high resistance to temperature variation in order to prevent it from any damage.

- It should have high permittivity in order to withstand the electrical stresses due to over voltages, switching surges, lightning

- It should be non-porous and free from impurities like cavity, void, crack etc.

- It should have high ratio of puncture strength to flashover.

- It should not be brittle.

- It should be non-hygroscopic.

Types of Electrical Insulator

The various types of insulators are as follows,

- Pin-type insulators

- Suspension type insulators

- Strain insulators

- Shackle insulators and

- Stay insulators.

Puncture in an Electrical Insulator

Puncture is an electric breakdown in an insulator and it is most severe but least frequent type of electrical breakdown. Whenever, the voltage across the insulator exceeds the puncture voltage, an arc will strike between the conductor and passes through the body of the insulator. Since, the arc produced during puncture passes through the whole body of the insulator, the complete insulator gets damaged and has to be replaced with a new one. In order to avoid puncture of insulators, the thickness of the porcelain disc has to be increased.

Whenever flash over occurs, there are chances that the insulator will continue to work. But, whenever a puncture occurs, there is no chance, that it will continue to work and the insulator has to be replaced. Hence for safety operation of the insulator, the insulator will be designed in such a way that flash over occurs before puncture. This can be ensured by keeping the value of safety factor as high as possible. The value of safety factor for a pin type insulator is about 10.