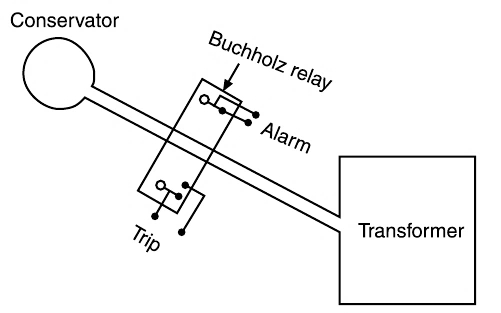

A Buchholz Relay is a gas-actuated safety device used in oil-immersed transformers to detect and protect against internal faults. It operates on the principle of gas accumulation or sudden oil flow caused by electrical faults inside the transformer. It is typically installed in the pipeline connecting the transformer’s main tank and the conservator.

What is a Buchholz Relay?

A Buchholz relay is a gas-actuated relay, mounted in the piping between the transformer tank and the conservator tank. This relay detects faults inside the transformer, such as internal short circuits, oil leakage, or overheating, by monitoring the flow and pressure of oil or detecting gas formation.

Working Principle of Buchholz Relay

The Buchholz relay operates based on the following principles:

- Gas Accumulation: During minor faults such as overheating or arcing inside the transformer, the insulation or oil decomposes, releasing gases. These gases accumulate in the relay chamber and displace the oil, causing the relay’s float to move downward, triggering the alarm circuit.

- Oil Flow Disturbance: In the event of a major fault, such as a short circuit, a surge of oil flows rapidly from the transformer tank to the conservator. This sudden flow tilts a flap (or vane) inside the relay, activating the trip circuit, which disconnects the transformer from the supply to prevent further damage.

Construction (or Parts) of Buchholz Relay

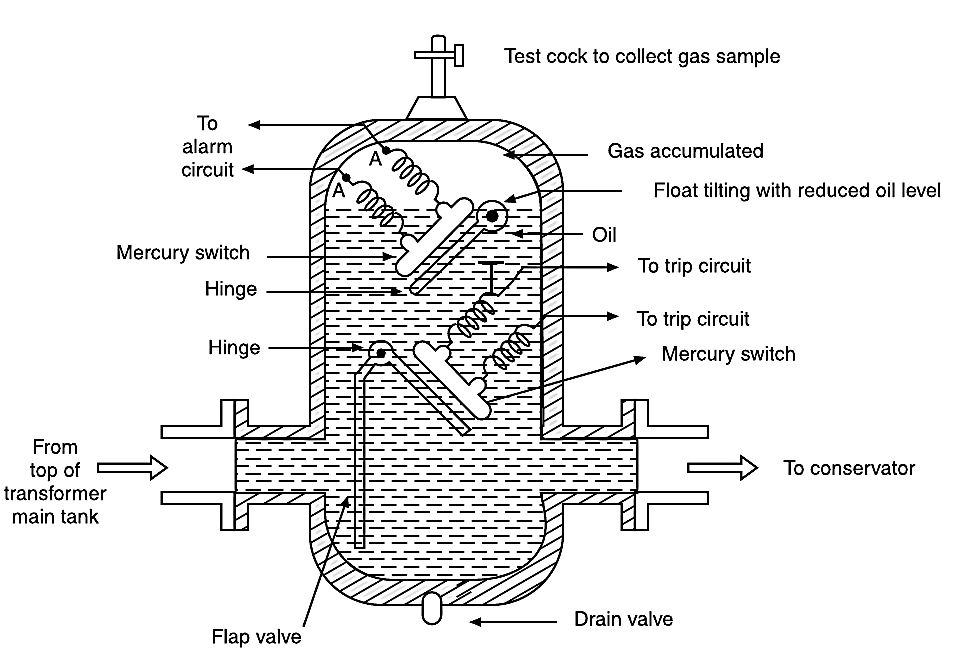

- Float and Mercury Switch: A float connected to a mercury switch detects the accumulation of gas at the top of the relay. When enough gas accumulates, the float tilts, activating the mercury switch to trigger an alarm.

- Flap Valve and Mercury Switch: A flap valve at the bottom of the relay is connected to another mercury switch. During sudden oil displacement caused by severe faults (e.g., short circuits), the oil flow tilts the flap, activating the mercury switch to trip the transformer.

- Oil Chamber: The relay is filled with transformer oil, which flows between the main transformer tank and the conservator.

- Gas Collection Space: Gas generated by internal faults rises to the top of the relay, displacing the oil and tilting the float.

- Test Cock: A valve to collect gas samples for analysis to determine the type of fault.

- Drain Valve: Used to drain oil from the relay for maintenance or testing.

- Hinges: Mechanically connect the float and flap to their respective mercury switches.

Working of Buchholz Relay

- Normal Operation: Oil flows freely between the transformer tank and conservator tank through the relay. The float and flap remain in their normal positions, keeping the mercury switches open.

- Minor Faults (Gas Accumulation): Internal faults like insulation breakdown generate gas due to decomposition of transformer oil. The gas displaces oil in the relay, causing the float to tilt downward. The tilting float closes the mercury switch connected to the alarm circuit, alerting the operator.

- Severe Faults (Sudden Oil Flow): High-intensity faults, such as short circuits, generate rapid oil flow towards the conservator. The oil flow tilts the flap downward, closing the mercury switch connected to the trip circuit. This action immediately disconnects the transformer from the power supply, preventing further damage.

Advantages of Buchholz Relay

- Early Fault Detection: Detects internal faults like insulation failure or oil overheating at an early stage.

- Prevention of Major Damage: Isolates the transformer promptly in case of severe faults, preventing further damage.

- Simple Construction: Relatively simple design and reliable operation.

- Dual Protection: Provides both alarm (for minor faults) and trip (for severe faults) functions.

- Fault Diagnosis: Gas sample analysis helps determine the type and nature of faults.

Limitations of Buchholz Relay

- Not Suitable for Dry Transformers: Only works in oil-filled transformers.

- Restricted to Slow-Developing Faults: Ineffective for very fast transient faults like lightning or external short circuits.

- Requires Maintenance: Gas analysis and relay calibration require periodic maintenance.

- False Alarms: Non-fault-related gas generation (e.g., oil degradation) can trigger alarms unnecessarily.

- Limited to Transformers with Conservators: Cannot be used in transformers without conservator tanks.

Uses of Buchholz Relay

- Power Transformers: Used in oil-immersed transformers rated above 500 kVA.

- Reactors: Applied in oil-filled reactors for fault detection.

- Industrial Transformers: Ensures safe operation in industrial power systems.

- Substation Equipment: Protects transformers in substations connected to the grid.

- Critical Electrical Installations: Used where transformer reliability is crucial, such as in hospitals and data centers.