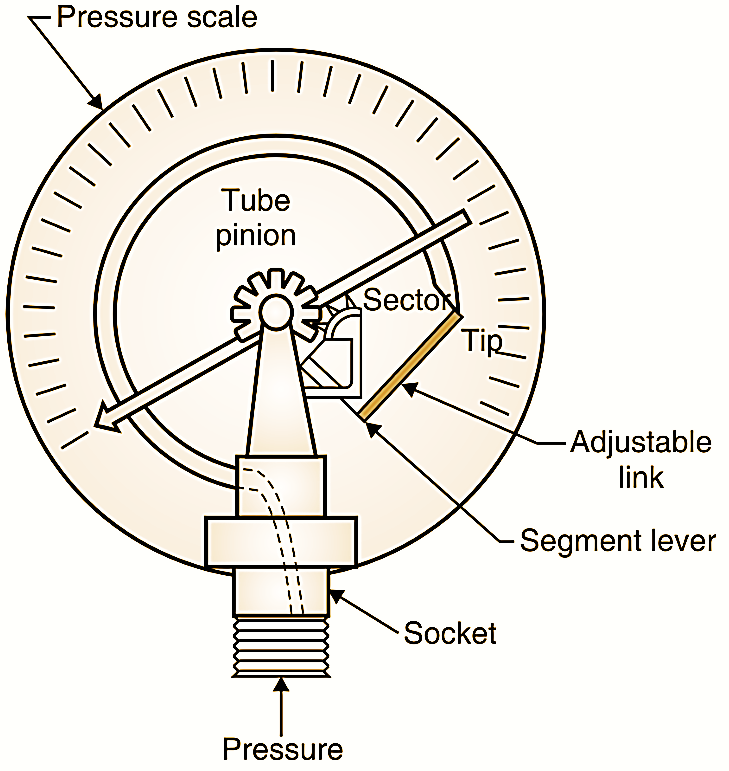

Figure 1: Bourdon Tube Pressure Gauge.

Working and Construction of Bourdon Tube Pressure Gauge

The Bourdon tube is the most frequently used pressure gauge because of its simplicity and rugged construction. It covers ranges from 0-15 psig to 0-100,000 psig, as well as vacua from 0 to 30 inches of mercury. It consists of a long thin-walled cylinder of non-circular cross- section, sealed at one end, made from materials such as phosphor bronze, steel and beryllium copper and attached by a light line work to the mechanism that operates the pointer. The other end of the tube is fixed and is open for the application of pressure which is to be measured.

The tube is soldered or welded to a socket at the base, through which pressure connection is made. It is shown in Fig. 1.

As fluid under pressure enters the Bourdon tube, it tries to change the section of the tube from oval to circular, and this tends to straighten out the tube. The resulting movement of the free end of the tube causes the pointer to move over the scale. The tip of the Bourdon tube is connected to a segmental lever through an adjustable length link. The segmental lever end on the segment side is provided with a rack which meshes to a suitable pinion mounted on a spindle.

The segmental lever is suitably pivoted and the spindle holds the pointer. A hairspring is sometimes used to fasten the spindle to the frame of the instrument to provide the necessary tension for proper meshing of the gear teeth, thereby freeing the system from backlash. Any error due to friction in the spindle bearing is known as ‘lost motion’.

Bourdon tubes are made of a number of materials depending upon the fluid and the pressure for which they are used, such as phosphor bronze, alloy steel, stainless steel, monel metal and beryllium copper. For adequate reliability, the materials must have good elasticity.

Bourdon tubes are generally made in c, helical or spiral shape.

Adjustments :

a) Multiplication adjustment : Due to compound stresses developed in the Bourdon tube, actual travel is non- linear in nature. However, for a small travel of the tip this can be considered to be linear and parallel to the axis of the link. The small linear tip movement is matched with a rotational pointer movement. This is known as multiplication and can be adjusted by adjusting the length of the lever. A shorter lever gives larger rotation for the same amount of tip travel.

b) Angularity : When the linear motion of the tip is converted to a circular motion with the link lever and pinion attachment a one to one correspondence between them may not occur and a distortion results. This is known as ‘angularity’. Angularity can be minimized by adjusting the length of the link.

Advantages of Bourdon Tube Pressure Gauge

- Simple construction

- Time tested in applications

- Availability in a wide variety of ranges, including very high ranges.

- High accuracy.

- Low cost

- Adaptability to transducer designs for electronic instruments.

Disadvantages of Bourdon Tube Pressure Gauge

- Low spring gradient

- Susceptibility to shock and vibration.

- Susceptibility to hysteresis.