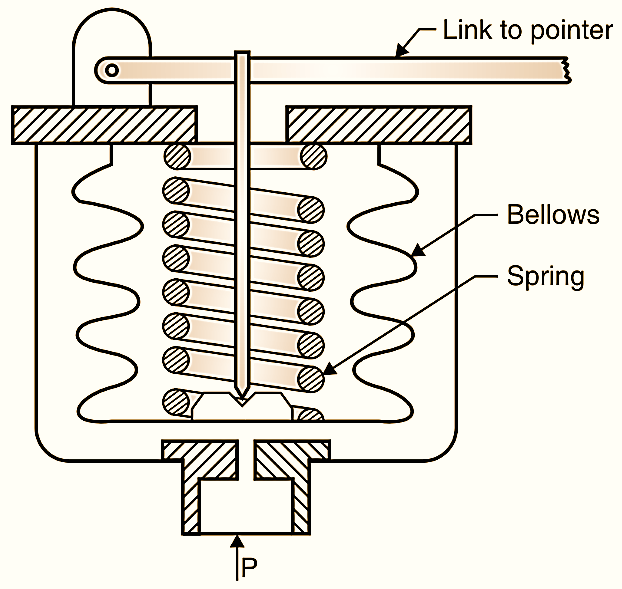

Figure 1: Bellows Pressure Gauge.

Working and Construction of Bellows Pressure Gauge

The bellows pressuree gauges are used for the measurement of absolute pressure. It is more sensitive than Bourdon tube gauges. It is generally used for the range down to 155.1 mm Hg (3 psi). It may be used for even lower pressures upto 40 mm Hg by making the bellows large enough.

The bellows are made of an alloy which is ductile, has high strength and retains its properties over long use i.e. has very little hysteresis effect. They are used in two forms.

In one arrangement, pressure is applied to one side of the bellows and the resulting deflection is counter balanced by a spring as shown in Fig. 1. This arrangement indicates gauge pressure. They are called as spring opposed bellow elements. They are very sensitive and are quite useful in working signaling and tripping devices because of the considerable amount of movement for a given change in pressure.

It is made of a metallic bellows enclosed in a shell which is connected to a pressure source. Pressure acting on the outside of the bellows compresses the bellows and moves its free end against the opposing force of the spring. A rod resting on the bellows transmits the motion to a pointer. Phosphor bronze is the commonly used material for bellows and the springs are of carefully heat treated metal.

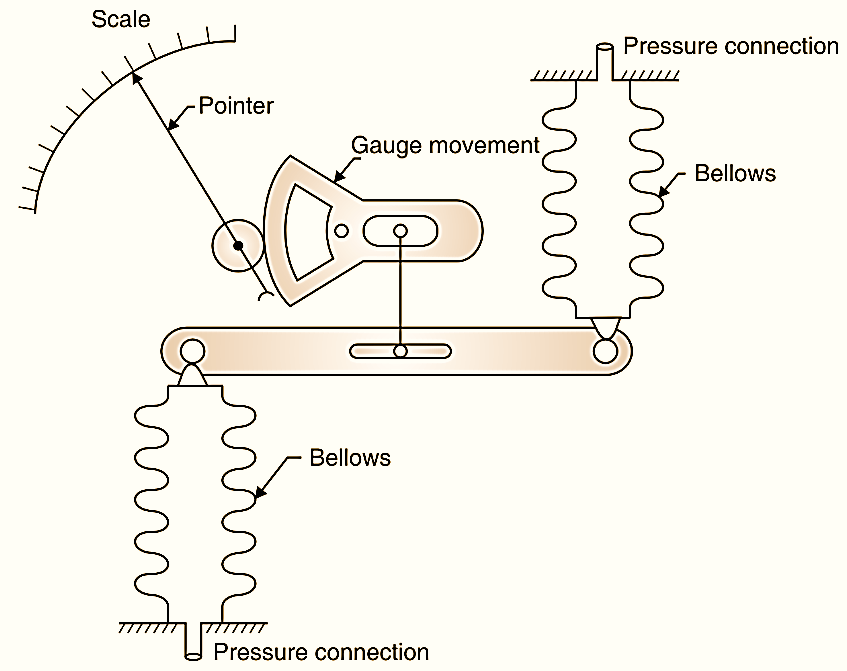

In another arrangement, the differential pressure is also indicated.

In this device, one pressure is applied to the inside of one sealed bellow while the other pressure is applied to the inside of another sealed bellow as shown in Fig. 2. By suitable linkage and calibration of the scale, the pressure difference is indicated on the scale. They are extremely useful for larger static pressures upto 2000 psi and larger differential pressures upto 50 psi.

Advantages of Bellows Pressure Gauge

- Moderate cost.

- Delivery of high force.

- Adaptability for absolute and differential pressures.

- Good in low to moderate pressure range.

Disadvantages of Bellows Pressure Gauge

- Ambient temperature compensation needed.

- Unsuitability for high pressures.

- Limited availability of metals and work-hardening of some of them.

- Unsuitability of its zero and the stiffness.

Hence, it is used only in conjunction with a reliable spring of appreciably higher stiffness for accurate characterization.