A carbon composition resistor is one of the oldest and most widely used types of fixed resistors in electrical and electronic circuits. Due to its simple construction, low cost, and wide resistance range, it has been extensively used in early electronic equipment, radios, amplifiers, and general-purpose circuits.

Although modern resistors such as carbon film and metal film resistors have replaced it in many applications, carbon composition resistors are still important from an academic and historical point of view and are used where high energy pulses must be handled.

What is a Carbon Composition Resistor?

Definition: A carbon composition resistor is a fixed resistor made by mixing finely powdered carbon with an insulating material such as resin or clay, molded into a cylindrical shape with metal leads attached at both ends. The resistance value depends on the ratio of carbon to insulating material. Higher carbon content gives lower resistance, while lower carbon content gives higher resistance.

Carbon Composition Resistor Diagram

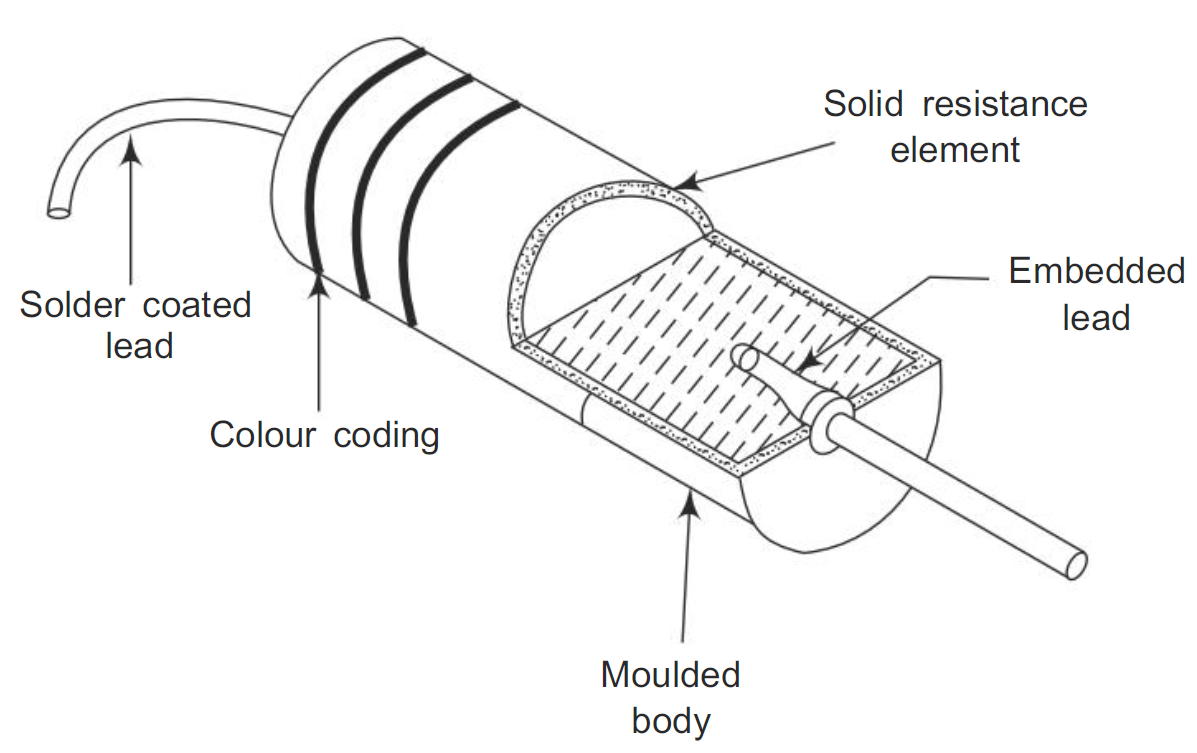

The diagram below shows the internal construction of a carbon composition resistor, including the molded body, solid resistance element, embedded leads, and color coding.

Construction of Carbon Composition Resistor

The construction of a carbon composition resistor is very simple compared to modern resistors. It does not involve any winding or thin film deposition process.

Main Parts of Carbon Composition Resistor

- Carbon Powder: Acts as the main resistive material.

- Insulating Binder: Resin or clay used to bind carbon particles.

- Solid Resistance Element: A molded cylindrical rod formed from the carbon mixture.

- Metal Leads: Tinned copper leads embedded at both ends.

- Moulded Plastic Body: Protects the resistor from moisture and damage.

- Colour Coding: Indicates resistance value and tolerance.

The carbon and insulating material are mixed in required proportions and compressed into a cylindrical shape. Leads are embedded at both ends, and the body is covered with molded plastic insulation. Carbon composition resistors are available in resistance ranges from a few ohms to hundreds of megaohms with typical power ratings from 1/8 W to 2 W.

Working Principle of Carbon Composition Resistor

The working of a carbon composition resistor is based on the basic principle of electrical resistance. When a voltage is applied across the resistor, current flows through the carbon particles. The resistance arises due to collisions of electrons with carbon particles and insulating material. Since carbon particles are randomly distributed, the current path is irregular, which results in higher electrical noise compared to modern resistors. However, this structure allows the resistor to withstand sudden voltage surges.

Types of Carbon Composition Resistors

Carbon composition resistors can be classified based on tolerance and application.

| Type | Tolerance | Features | Applications |

|---|---|---|---|

| Standard Carbon Composition Resistor | ±10% to ±20% | Low cost, simple design | General-purpose circuits |

| Precision Carbon Composition Resistor | ±5% | Better accuracy | Measuring instruments |

| High Voltage Carbon Resistor | ±10% | Can withstand high voltage | Power supplies |

| Pulse Rated Carbon Resistor | ±10% to ±20% | Handles high energy pulses | Surge protection circuits |

Advantages of Carbon Composition Resistor

- Simple and rugged construction

- Low manufacturing cost

- Wide resistance range

- Good performance at high temperatures

- Capable of withstanding high surge currents

Disadvantages of Carbon Composition Resistor

- Low accuracy compared to film resistors

- High electrical noise

- Resistance value changes with time

- Poor stability

- Large size for higher power ratings

Applications of Carbon Composition Resistor

Despite being replaced in many modern circuits, carbon composition resistors are still used in specific applications due to their unique properties.

- Surge and pulse handling circuits

- Power supply protection

- Audio amplifiers (vintage equipment)

- Radio and television receivers

- General-purpose electronic circuits

- Educational and laboratory experiments

Difference Between Carbon Composition Resistor and Carbon Film Resistor

| Parameter | Carbon Composition | Carbon Film |

|---|---|---|

| Accuracy | Low | High |

| Noise | High | Low |

| Stability | Poor | Good |

| Cost | Low | Moderate |

| Surge Handling | Excellent | Limited |

Conclusion

A carbon composition resistor is a fundamental electronic component known for its simple construction, wide resistance range, and ability to withstand high surge currents. Although it has limitations such as low accuracy and stability, it still plays an important role in pulse and surge applications. Understanding carbon composition resistors is essential for students and engineers

to grasp the evolution of resistor technology.