A valve type lightning arrester is one of the most widely used protective devices in power systems, particularly in transmission and distribution networks. Its main function is to protect electrical equipment—such as transformers, generators, lines, and substations—from high voltage surges caused by lightning, switching operations, and transient faults.

A valve type lightning arrester safely diverts excessive surge voltage to the earth before it can damage power system equipment.

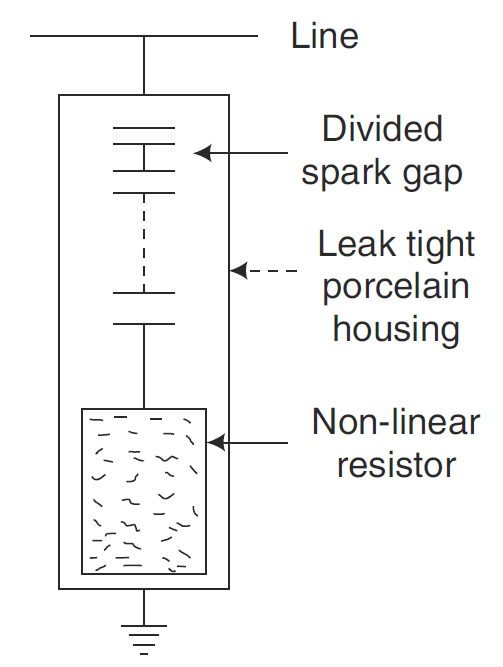

Fig 1: Valve Type Lightning Arrester Construction

Definition of Valve Type Lightning Arrester

A valve type lightning arrester is a protective device that consists of two major parts:

- Spark gap section – breaks down during overvoltage to allow surge current to pass.

- Non-linear resistor section (Valve element) – limits the surge current and voltage due to its non-linear V–I characteristics.

When a high voltage surge strikes the power line, the arrester provides a low-resistance path to ground and protects the system. After the surge is discharged, the arrester automatically returns to its high-resistance state.

Need for Valve Type Lightning Arrester

Lightning strikes or switching surges can cause extremely high voltages. These voltages may damage insulation, lead to flashovers, interrupt supply, or permanently damage transformers and generators.

Diagram of Valve Type Lightning Arrester

The figure 1 clearly shows the spark gap, non-linear resistor, porcelain housing, and grounding arrangement. These components work together to discharge the surge safely.

Construction of Valve Type Lightning Arrester

The construction can be divided into three primary sections:

1. Divided Spark Gap

- Consists of several spark gaps connected in series.

- The gaps break down only when the applied surge voltage exceeds a certain threshold.

- Prevents unnecessary breakdown during normal system voltage.

2. Leak-Tight Porcelain Housing

- Provides mechanical protection.

- Keeps the internal parts moisture-free.

- Maintains dielectric strength of the arrester.

3. Non-Linear Resistor (Valve Element)

- Made of silicon carbide (SiC) or zinc oxide (ZnO).

- Shows highly non-linear voltage-current characteristics.

- At normal voltage → high resistance.

- At surge voltage → resistance drops sharply, allowing surge current to pass.

Working Principle of Valve Type Lightning Arrester

The arrester works based on the combination of spark gaps and non-linear resistance. The operation can be explained in three stages:

Stage 1: Normal Operating Conditions

- The spark gap does not conduct.

- The arrester presents a high resistance path.

- No current flows through the arrester.

Stage 2: During Lightning/Surge Voltage

- Surge voltage appears on the power line.

- The spark gap breaks down, creating a path for surge current.

- The non-linear resistor drops its resistance rapidly.

- The surge current flows through the arrester to ground.

- The protected equipment remains safe.

Stage 3: After Surge

- The line voltage returns to normal.

- Spark gap extinguishes the arc due to reduced voltage.

- Non-linear resistor returns to high resistance.

- The arrester becomes non-conducting again.

Types of Valve Type Lightning Arresters

| Type | Construction / Valve Element | Key Characteristics | Advantages | Typical Use / Voltage Range |

|---|---|---|---|---|

| Silicon Carbide (SiC) Valve Arrester | Series of SiC resistor blocks (valve elements) plus divided spark gaps in porcelain housing. | Non-linear V–I curve but less steep than ZnO; relies on spark gaps to limit leakage at normal voltages. | Robust, proven technology; tolerant to high energy surges; simple replacement parts. | Medium to high voltage lines; historically common for MV/HV (up to several 100 kV with modular designs). |

| Zinc Oxide (ZnO / MOV) Valve Arrester | ZnO metal-oxide varistor blocks (valve stack). Often gapless design or with minimal/gapped protection. | Very steep non-linear V–I characteristic → excellent clamping voltage and low leakage under normal voltage. | Superior energy absorption, compact, low maintenance, improved protection and longer life vs SiC. | Distribution to transmission systems; MV & HV substations; widely used across 11 kV to extra high voltage levels. |

| Gapped Valve Arrester (Series Spark Gaps + Valve) | Valve (SiC or ZnO) combined explicitly with divided spark gaps sized to control breakdown behavior. | Spark gaps ensure predictable flashover threshold; valve controls residual voltage and energy dissipation. | Controlled discharge, improved protection coordination, easy to retrofit adjustable gaps. | Where coordination with protection devices is needed; older installations and some EHV designs. |

| Gapless / Non-Gapped Valve Arrester | Mostly ZnO MOV stacks without series spark gaps (or with very small gaps). | Self-restoring under transient; no deliberate spark gap → continuous clamping action during surge. | Simpler construction, compact, very low residual voltage, minimal maintenance. | Modern distribution transformers, switchgear, and new substations — popular for MV/HV applications. |

| Modular / Multi-Column Valve Arrester | Multiple modular valve columns (SiC or ZnO) inside one housing for higher energy or redundancy. | Scalable energy handling; columns may be paralleled/series-arranged for required ratings. | High energy capability, easy servicing (replace a module), higher reliability via redundancy. | High-energy locations (EHV lines, large transformers, critical substations). |

Note: ZnO-based valve arresters are the modern standard due to superior non-linear behaviour and low maintenance. SiC types remain in service in many older installations. Selection should consider system voltage, required energy rating, coordination with protection devices, and environmental sealing.

Advantages of Valve Type Lightning Arrester

- Very fast response to surges.

- Non-linear resistance gives excellent control of surge voltage.

- Stable operation under extreme environmental conditions.

- Leakage current under normal voltage is extremely low.

- Provides complete protection to transformers and lines.

- Long service life with minimum maintenance.

Disadvantages of Valve Type Lightning Arrester

- Older SiC types require maintenance and periodic inspection.

- Performance decreases if moisture enters the porcelain housing.

- Less effective if spark gaps deteriorate.

- Installation costs may be high in EHV systems.

Applications of Valve Type Lightning Arrester

These arresters are widely used in power systems such as:

- Transmission and distribution lines

- Substations

- Power transformers

- Generator protection

- Switchgear installations

- Industrial power plants

Conclusion

Valve type lightning arresters form the backbone of surge protection in electrical power systems. They combine spark gaps and non-linear resistors to ensure fast discharge of lightning surges while keeping the system safe from overvoltage damage. Their reliable and automatic operation makes them indispensable for substations, transformers, and overhead transmission lines.

Modern ZnO-type valve arresters have improved non-linear characteristics, reduced maintenance, and better energy-handling capability than traditional SiC arresters. With growing demand for power stability, the role of lightning arresters in system protection continues to be more important than ever.