A Pin Insulator is a type of electrical insulator mounted directly on a pole or tower to support conductors and insulate them from the supporting structure. It is one of the oldest and most commonly used insulators for low to medium voltage transmission lines. Pin insulators are typically made of porcelain, glass, or composite polymer materials.

Construction of a Pin Insulator

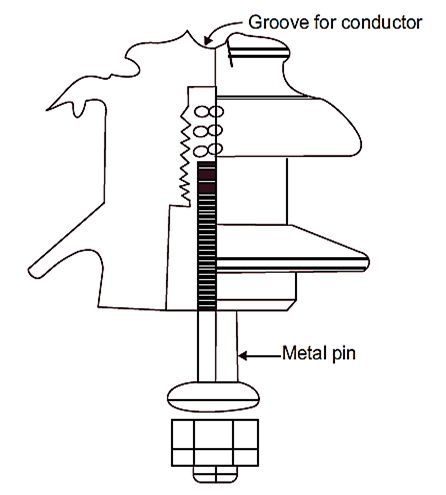

- Insulating Body: Made of porcelain, glass, or polymer. The body has a smooth surface to reduce the accumulation of dirt and pollutants.

- Metal Fitting (Metal Pin): A metal pin is embedded into the bottom of the insulator. This pin is secured to the pole or cross-arm.

- Groove for Conductor: The upper part of the insulator has a groove or channel for holding the conductor. The conductor is secured with binding wire.

- Design: Designed with sheds or ribs to increase the creepage distance and prevent surface leakage due to rain, dust, or pollution.

Working of a Pin Insulator

- The conductor is placed in the groove at the top of the insulator and secured using binding wire.

- The pin insulator provides mechanical support to the conductor and electrically insulates it from the grounded support structure.

- The shed-like structure helps prevent water from forming a continuous film, thereby reducing the chances of electrical leakage during rain or wet conditions.

Types of Pin Insulators

- Single Piece Pin Insulator:

- Used for low voltage applications (up to 11 kV).

- Consists of a single insulating unit.

- Multiple Piece Pin Insulator:

- Used for higher voltage applications (33 kV and above).

- Made of two or more pieces of insulating material, cemented together for improved strength and durability.

Advantages of Pin Insulators

- Simple Design: Easy to install and maintain.

- Cost-Effective: Affordable solution for low to medium voltage lines.

- Mechanical Strength: Capable of withstanding significant mechanical loads.

- Reliable: Performs well under normal environmental conditions.

Disadvantages of Pin Insulators

- Limited Voltage Range: Not suitable for very high-voltage applications due to size and design limitations.

- Fragility: Porcelain and glass materials are prone to breakage.

- High Weight: Heavier than other insulator types, requiring strong supporting structures.

- Creepage Distance: Requires larger insulators for higher voltages, increasing cost and complexity.

Applications of Pin Insulators

- Distribution Lines: Widely used in low to medium voltage distribution networks.

- Rural Electrification: Commonly found in rural power lines due to cost efficiency.

- Low and Medium Voltage Transmission: Used up to voltage levels of 33 kV.

- Substations: Occasionally used in substations for supporting conductors.