An HRC (High Rupturing Capacity) fuse is a type of fuse used in electrical systems to provide overcurrent protection. It is designed to handle high fault currents without rupturing the fuse casing or causing an explosion.

What is HRC Fuse?

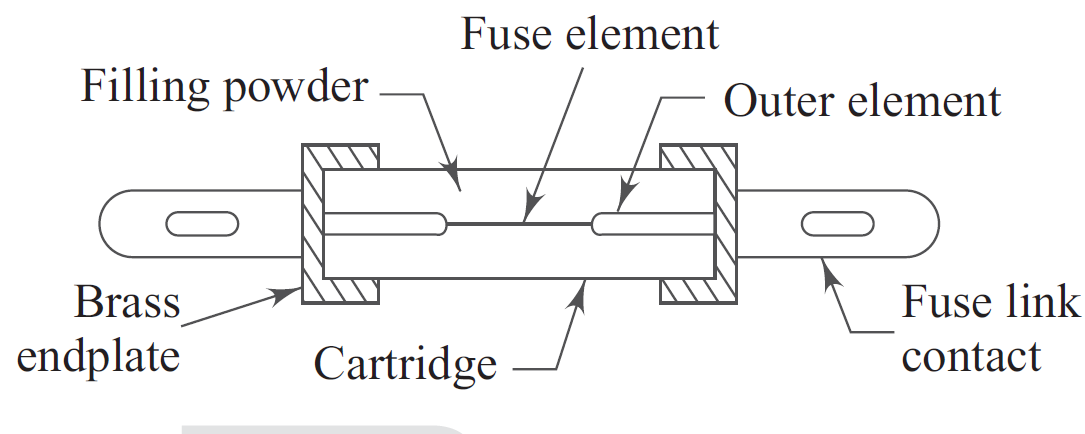

An HRC fuse is constructed with a high-breaking-capacity element enclosed in a cartridge filled with arc-extinguishing material, ensuring reliable protection for circuits under both normal and fault conditions.

Parts of HRC Fuse

- Fuse Element: A specially designed metallic wire or strip that melts and breaks the circuit during overcurrent conditions. Common materials include silver or copper.

- Cartridge: The body of the fuse, usually made of ceramic or fiber glass, providing insulation and mechanical strength.

- Filling Powder: The space inside the cartridge is filled with quartz or silica sand, which acts as an arc-extinguishing medium.

- Outer Element: The outer casing that holds the cartridge and provides a sealed environment to prevent damage during fault clearing.

- Brass Endplates (or Terminals): Connects the fuse to the electrical circuit. It provides a path for current flow when the fuse is intact.

- Fuse Link Contacts: Conductive parts that connect the fuse element to the electrical terminals.

Working of HRC Fuse

- Normal Operation: Under normal current, the fuse element carries the load without significant heating or melting.

- Overcurrent Condition: When the current exceeds the fuse’s rated capacity (due to a fault), the fuse element heats up and melts.

- Arc Formation: The melting of the fuse element creates an arc, which is confined within the cartridge.

- Arc Extinguishing: The filling powder (usually silica sand) absorbs the energy of the arc, converting it into heat and solidifying into glass-like material. This action extinguishes the arc quickly.

- Circuit Break: The melting and arc-extinguishing processes ensure that the circuit is broken safely, isolating the faulted section.

Types of HRC Fuses

| Type | Design | Applications | Advantages |

|---|---|---|---|

| Blade-Type HRC Fuse (NH Fuse) | Blade-shaped terminals, ceramic or fiberglass body | Low-voltage circuits, motor and cable protection | Compact, reliable fault isolation |

| Cartridge-Type HRC Fuse | Cylindrical body, filled with arc-quenching material | Domestic appliances, low/medium voltage circuits | Easy to replace, simple construction |

| Motor Protection HRC Fuse | Time-delay characteristics for motor startup | Overcurrent and short-circuit protection for motors | Prevents unnecessary tripping |

| High-Voltage HRC Fuse | Robust design for high voltages | Transformers, substations, high-voltage systems | Handles large fault currents |

| DIN-Type HRC Fuse | Standardized design for industrial use | Control panels, distribution boards | Ensures system compatibility |

| Liquid-Filled HRC Fuse | Filled with liquid for arc suppression | High-voltage systems | Efficient arc suppression |

| Expulsion-Type HRC Fuse | Fiber tube ejects arc during operation | Medium and high-voltage outdoor circuits | Economical for outdoor use |

| Drop-Out HRC Fuse | Mechanically drops when blown | Distribution transformers, outdoor circuits | Visible fault indication |

Advantages of HRC Fuses

- High Breaking Capacity: Can handle large fault currents without damage.

- Reliable Protection: Provides precise and predictable protection under fault conditions.

- Compact Design: Space-saving and easy to install.

- Arc Extinction: Filler material ensures efficient arc suppression, reducing damage.

- Durability: Long operational life under normal conditions.

Disadvantages of HRC Fuses

- Non-Reusable: Once blown, the fuse must be replaced.

- Limited Protection: Cannot protect against sustained overloads effectively; circuit breakers are better suited for such conditions.

- Cost: Higher initial cost compared to ordinary fuses.

- Replacement Time: Requires manual intervention to replace after tripping.

- No Indication of Fault: Unlike circuit breakers, HRC fuses do not visually indicate the cause of a fault.

Uses of HRC Fuses

- Transformer Protection: To prevent damage from faults in power transformers.

- Motor Protection: To safeguard motors from overloads and short circuits.

- Industrial Equipment: Used in heavy machinery to ensure safe operation.

- High Voltage Circuits: Protects circuits operating at high voltages.

- Control and Distribution Panels: For isolating faulty circuits to maintain system stability.

Conclusion

HRC fuses are essential in ensuring electrical safety, particularly in high-current and high-voltage applications. Their ability to handle large fault currents reliably and extinguish arcs efficiently makes them a popular choice in industrial and power systems. However, their non-reusable nature and limited overload protection capability are some limitations that should be considered during selection.