An underground cable is a type of electrical cable used for transmitting and distributing electricity beneath the ground’s surface. Unlike overhead transmission lines, these cables are concealed, offering better protection from external environmental factors, enhanced safety, and improved aesthetic appeal. Underground cables are widely used in urban areas, industrial installations, and specialized applications like submarine power transmission.

Construction of Underground Cable

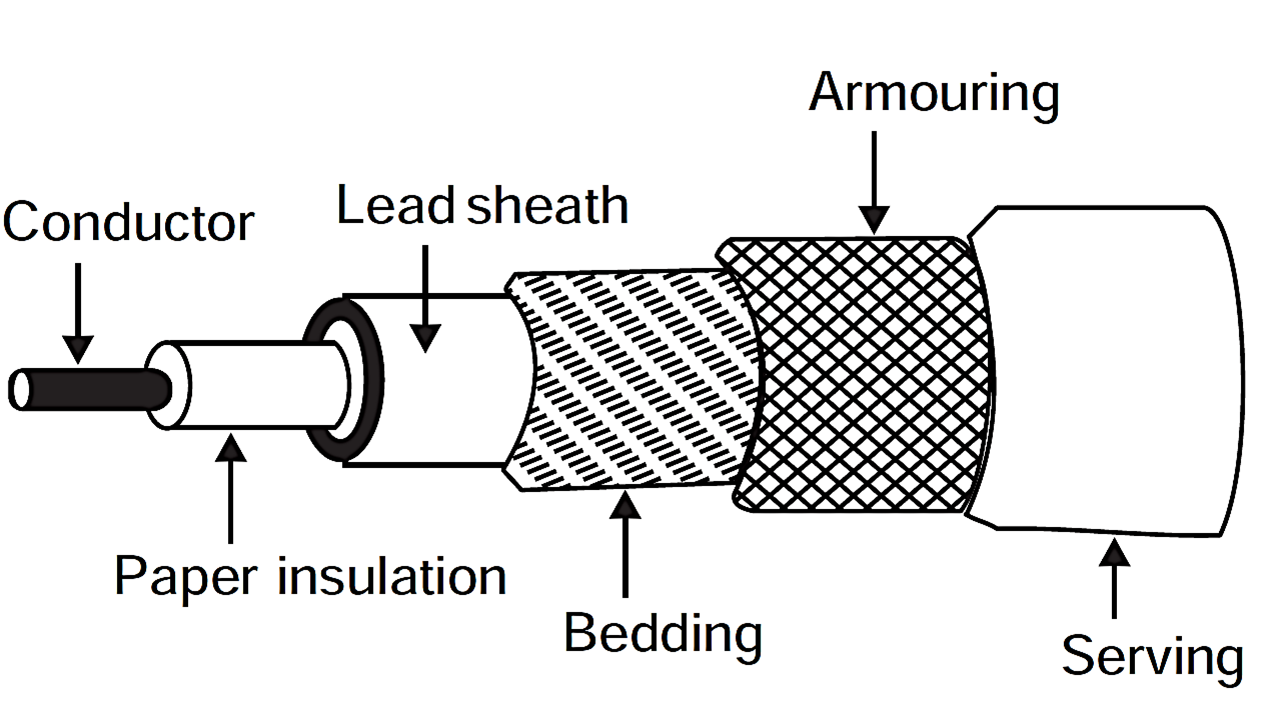

An underground cable is designed to carry electrical power while being buried beneath the ground. The construction ensures reliability, mechanical strength, insulation, and protection against environmental hazards. Below are the key components of an underground cable:

- Conductor: The core of the cable that carries the current. It is usually made of materials with high conductivity such as copper or aluminum.

- Paper Insulation: It provides electrical insulation to prevent current leakage. It often composed of layers of impregnated paper or polymer materials like XLPE or PVC for higher voltage cables.

- Lead Sheath: A metallic sheath (commonly lead or aluminum) surrounds the insulation. It protects the cable from moisture, gases, and other external contaminants.

- Bedding: A layer of soft material (e.g., jute or PVC) applied over the lead sheath. It acts as a protective cushion for the sheath and provides mechanical strength to the cable.

- Armouring: A layer of steel or other metallic wires or strips wrapped around the bedding. It protects the cable from mechanical damage, such as crushing or impacts. It adds tensile strength, allowing the cable to withstand pulling forces during installation.

- Serving: The outermost layer, typically made of a tough material such as PVC or bitumen. It protects the armouring and the entire cable from environmental elements like moisture, chemicals, and abrasion.

Types of Underground Cables

| Type | Voltage Rating | Application |

|---|---|---|

| Low Tension (LT) Cables | Up to 1kV | Used in domestic and industrial low-voltage systems. |

| High Tension (HT) Cables | 1kV to 11kV | Power transmission in industrial and urban areas. |

| Super Tension (ST) Cables | 11kV to 33kV | Used for power transmission over medium distances. |

| Extra High Tension (EHT) Cables | 33kV to 66kV | For long-distance power transmission in high-demand areas. |

| Extra Super Voltage (ESV) Cables | Above 66kV | Used in major power grids and substations. |

Underground cables are categorized based on insulation material, construction, and application. Here are the primary classifications:

A. Based on Insulation Material

- Paper-Insulated Lead-Covered (PILC) Cables:

- Insulated with layers of impregnated paper and covered with lead.

- Durable but less commonly used due to advancements in insulation materials.

- PVC-Insulated Cables:

- Flexible, flame-retardant, and resistant to chemicals.

- Suitable for low and medium voltage applications.

- XLPE-Insulated Cables:

- Offers excellent thermal resistance and dielectric properties.

- Preferred for modern high-voltage applications.

- Rubber-Insulated Cables:

- Water-resistant and flexible.

- Commonly used in temporary installations and harsh environments.

B. Based on Construction

- Single-Core Cables:

- Contain a single conductor.

- Used in applications where electromagnetic interference is negligible.

- Multi-Core Cables:

- Contain multiple conductors in one sheath.

- Suitable for complex installations like control and communication systems.

C. Based on Application

- Power Cables: Transmit and distribute electrical power.

- Control Cables: Used for instrumentation and control systems.

- Communication Cables: Facilitate data and telecommunication networks.

- Submarine Cables: Specifically designed for underwater applications.

Advantages of Underground Cable

- Reduced Maintenance: Protected from weather-related damages such as storms, lightning, or ice. It requires less frequent inspection and repair compared to overhead lines.

- Enhanced Safety: Reduces risks of electrical hazards caused by exposed or damaged wires.

- Reliability: Less prone to interruptions caused by environmental factors or human interference.

- Space Efficiency: Ideal for areas with limited space, such as cities and industrial zones.

- Lower Electromagnetic Interference (EMI): Ensures minimal interference with nearby electronic and communication systems.

Disadvantages of Underground Cable

- High Installation Costs: Requires expensive trenching, advanced materials, and skilled labor.

- Complex Maintenance: Locating and repairing faults can be time-consuming and costly.

- Limited Flexibility: Difficult to modify or relocate once installed.

- Heat Dissipation Issues: Underground cables may overheat due to limited air circulation.

- Environmental Challenges: Trenching and installation can disrupt soil and underground ecosystems.

Applications of Underground Cable

Underground cables are used in a variety of settings, including:

- Urban Power Distribution: Preferred in cities and densely populated areas to avoid space constraints and improve aesthetics.

- Industrial Installations: Provide reliable power supply to factories, refineries, and manufacturing units.

- Submarine Applications: Used to transmit electricity across water bodies like seas, rivers, and oceans. Examples include inter-island power links and offshore wind farm connections.

- Renewable Energy Projects: Connect solar farms, wind turbines, and hydropower stations to the grid.

- Transportation Systems: Power railway systems, metro networks, and airport facilities.

- Defense and Critical Infrastructure: Ensure secure and uninterrupted power supply to sensitive installations.

- Data Centers and Telecommunication Networks: Provide reliable power and connectivity for high-demand facilities.