Diaphragms are widely used for pressure measurements particularly in a very low ranges (0 to 4 mmHg). They can be flat, corrugated or dished plates and the choice depends on the strength and amount of deflection desired.

Working and Construction of Diaphragm Pressure Gauge

In high precision instruments the diaphragms are generally used in a pairs, back to back, to form an elastic capsule. Metallica and slack are two types of diaphragm which are generally used.

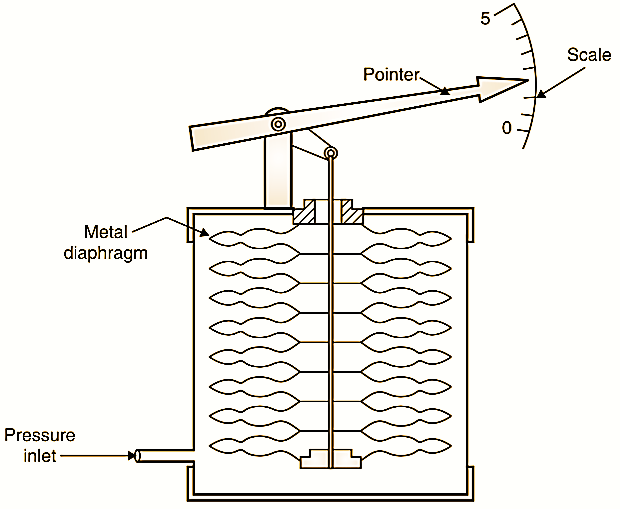

1. Metallic diaphragm:

Figure 1: Metallic Diaphragm.

Metallic diaphragm gauge consists of a thin flexible diaphragm made of materials such as brass or bronze. It is shown in Fig. 1. A pointer is attached to diaphragm. The force of pressure against the effective area of the diaphragm causes a deflection of the diaphragm. In some cases the deflection of the diaphragm is opposed by the spring qualities of the diaphragm itself and in other cases a spring is added to limit the deflection of the diaphragm. The motion of the diaphragm operates an indicating instrument.

This type of gauge is capable of working in any position and is portable, and hence well adapted for use or for installation in moving equipment’s such as aircrafts.

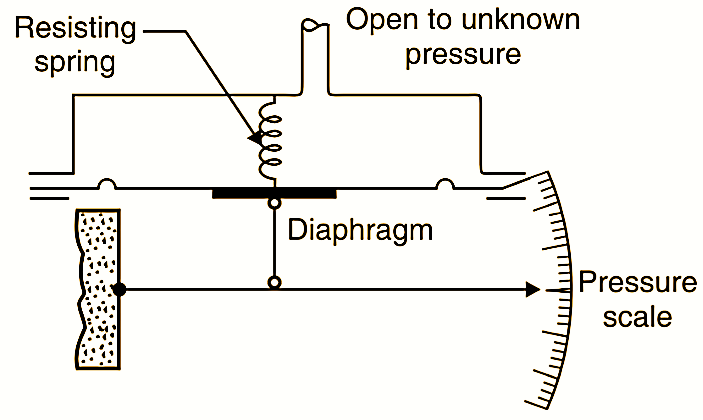

2. Slack diaphragm :

Figure 2: Slack Diaphragm.

Slack diaphragm gauge is shown in Fig. 2. It is made of rubber or other flexible materials. It is used to measure pressure below the atmospheric pressure. The full range from atmospheric pressure to a perfect vacuum is only 14.7 psi. As this gauge has slack diaphragm it can move by a large distance in response to a small pressure change. A slack diaphragm gauge with a weak spring and a large are can be used over pressure ranges as low as 0.01 to 0.4 mm Hg with accuracy of 1-2 %.

Advantages of Diaphragm Pressure Gauge

- Moderate cost.

- High over range characteristics.

- Adaptability to absolute and differential pressure measurement.

- Good linearity.

- Availability in several materials for good corrosion resistance.

- Small size.

- Adaptability to slurry services.

Disadvantages of Diaphragm Pressure Gauge

- Lock of good vibration and shock resistance.

- Difficult to repair.

- Limited to relatively low pressures.